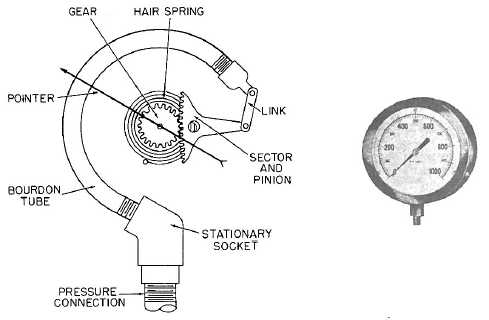

Figure 9-4.-The Bourdon gauge.

Bourdon Gauge

The Bourdon gauge is shown in figure 9-4. It

works on the same principle as that of the snakelike,

paper party whistle you get at a New Year party,

which straightens when you blow into it.

Within the Bourdon gauge is a thin-walled metal

tube, somewhat flattened and bent into the form of a

C. Attached to its free end is a lever system that

magnifies any motion of the free end of the tube. On

the fixed end of the gauge is a fitting you thread into

a boiler system. As pressure increases within the

boiler, it travels through the tube. Like the snakelike

paper whistle, the metal tube begins to straighten as

the pressure increases inside of it. As the tube

straightens, the pointer moves around a dial that

indicates the pressure in psi.

The Bourdon gauge is a highly accurate but

rather delicate instrument. You can easily damage it.

In addition, it malfunctions if pressure varies rapidly.

This problem was overcome by the development of

another type of gauge, the Schrader. The Schrader

gauge (fig. 9-5) is not as accurate as the Bourdon, but

it is sturdy and suitable for ordinary hydraulic

pressure measurements. It is especially suitable for

fluctuating loads.

In the Schrader gauge, liquid pressure actuates

a piston. The pressure moves up a cylinder against

the resistance of a spring, carrying a bar or indicator

with it over a calibrated scale. The operation of this

gauge eliminates the need for cams, gears, levers,

and bearings.

Diaphragm Gauge

The diaphragm gauge gives sensitive and

reliable indications of small pressure differences. We

use the diaphragm gauge to measure the air pressure

in the space between inner and outer boiler casings.

In this type of gauge, a diaphragm connects to a

pointer through a metal spring and a simple linkage

system (fig. 9-6). One side of the diaphragm is

exposed to the pressure being measured, while the

other side is exposed to the pressure of the

atmosphere. Any increase in the pressure line moves

the diaphragm upward against the spring, moving

the pointer to a higher reading. When the pressure

decreases, the spring moves the diaphragm

downward, rotating the pointer to a lower reading.

Thus, the position of the pointer is balanced between

the pressure pushing the diaphragm upward and the

spring action pushing down. When the gauge reads 0,

the pressure in the line is equal to the outside air

pressure.

MEASURING AIR PRESSURE

To the average person, the chief importance of

weather is reference to it as an introduction to

general conversation. At sea and in the air, advance

knowledge of what the weather will do is a matter of

great concern

9-4