Theoretically, the winch would have to work at a

rate of 12 horsepower to raise the anchor in 2 minutes.

Of course, you’ve left out all friction in this problem, so

the winch motor would actually have to be larger than

12 hp.

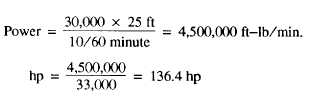

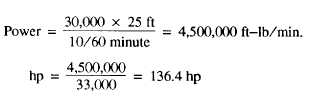

You raise planes from the hangar deck to the flight

deck of a carrier on an elevator. Some place along the

line, an engineer had to figure out how powerful the

motor had to be to raise the elevator. It’s not too tough

when you know how. Allow a weight of 10 tons for the

elevator and 5 tons for the plane. Suppose that you want

to raise the elevator and plane 25 feet in 10 seconds and

that the overall efficiency of the elevator mechanism is

70 percent. With that information you can figure what

the delivery horsepower of the motor must be. Set up

the formulas:

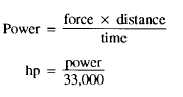

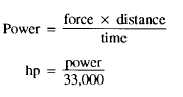

Substitute the known values in their proper places,

and you have:

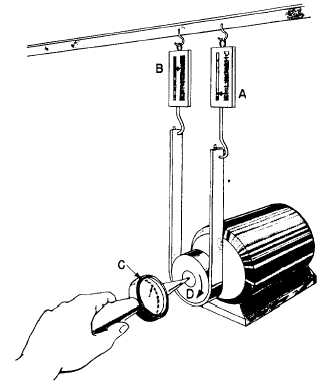

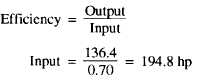

So, you need 136.4 horsepower if the engine has 100

percent overall efficiency. You want to use 70 percent

efficiency, so you use the formula:

This is the rate at which the engine must be able to

work. To be on the safe side, you’d probably select a

200-horsepower auxiliary to do the job.

FIGURING THE HORSEPOWER

RATING OF A MOTOR

You have probably seen the horsepower rating plates

on electric motors. You may use several methods to

determine this rating. One way to find the rating of a

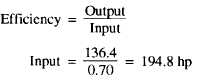

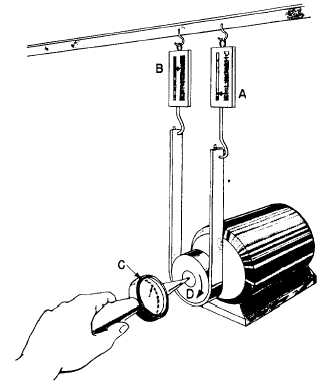

Figure 8-3.-A prony brake.

motor or a steam or gas engine is with the use of the

prony brake. Figure 8-3 shows you the prony brake

setup. A pulley wheel is attached to the shaft of the

motor and a leather belt is held firmly against the

pulley. Attached to the two ends of the belts are spring

scales. When the motor is standing still, each scale

reads the same— 15 points. When the pulley turns in a

clockwise direction, the friction between the belt and

the pulley makes the belt try to move with the pulley.

Therefore, the pull on scale A will be greater than

15 pounds, and the pull on scale B will be less than

15 pounds.

Suppose that scale A reads 25 pounds and scale B

reads 5 pounds. That tells you the drag, or the

force against which the motor is working, is

25 – 5 = 20 pounds. In this case the normal speed of

the motor is 1,800 revolutions per minute (rpm) and the

diameter of the pulley is 1 foot.

You can find the number of revolutions by holding

the revolution counter (fig. 8-3, C) against the end of the

shaft for 1 minute. This counter will record the number

of turns the shaft makes per minute. The distance

(D) that any point on the pulley travels in 1 minute is

8-3