Chapter 4—REDUCTION GEARS AND RELATED EQUIPMENT

grooved to accommodate the rings. As they glide

through the reservoir of oil at the bottom, the

rings carry some of the oil along to the top of the

shaft journal.

On some steam driven ships, the most recent

line shaft bearing design employs oiler discs

instead of oiler rings for lubrication. At very low

speeds (i.e., when the shaft is jacked for 24 hours

while the turbines are cooling), the oil rings tend

to slip and lubrication is sometimes inadequate.

The oiler discs are clamped to propulsion shaft

and have cavities at the periphery which carry oil

to the top of the bearing regardless of the shaft

speed.

Spring bearing temperatures and oil levels

should be checked hourly while underway. At

least once each year, the bearings should be

inspected, clearances taken, and any defects

corrected.

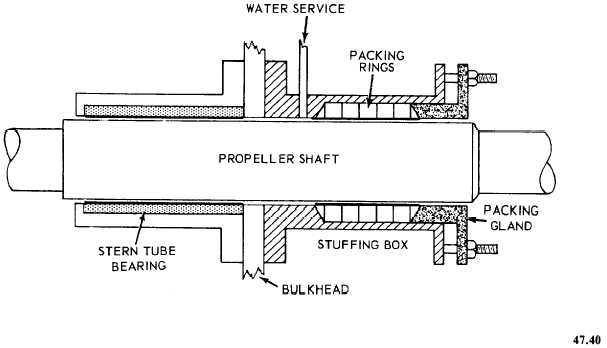

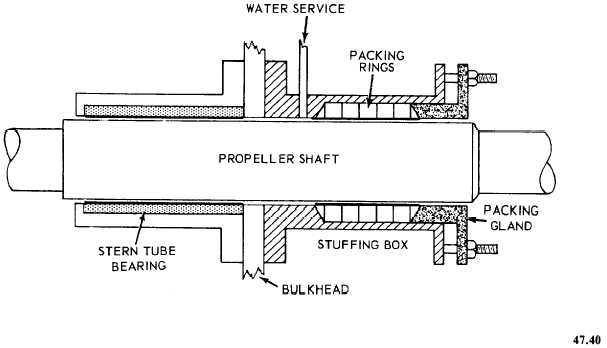

STERN TUBE AND STERN

TUBE BEARINGS

The hole in the hull structure for accom-

modating the propeller shaft to the outside of the

hull is called the stern tube. The propeller shaft

is supported in the stern tube by two bearings—

one at the inner end and one at the outer end of

the stern tube—called stern tube bearings. At the

inner end of the stern tube there is a stuffing box

containing the packing gland (figure 4-4), which

is generally referred to as the stern tube gland.

The stern tube gland seals the area between the

shaft and stern tube but allows the shaft to rotate.

The stuffing box is flanged and bolted to the

stern tube. Its casing is divided into two

compartments—the forward space which is the

stuffing box proper, and the after space, provided

with a flushing connection, designed to maintain

a positive flow of water through the stern tube

for lubricating, cooling, and flushing. This

flushing connection is supplied by the firemain.

A DRAIN CONNECTION is provided both for

testing for the presence of cooling water in the

bearing and for permitting sea water to flow

through the stern tube and cool the bearing when

underway, where natural seawater circulation is

employed.

The gland for the stuffing box is divided

longitudinally into two parts. The gland bolts are

long enough to support the gland when the latter

is withdrawn at least 1 inch clear of the stuffing

Figure 4-4.—Stern tube stuffing box and gland.

4-9