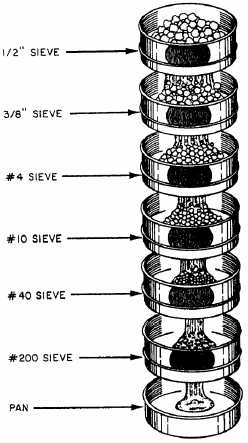

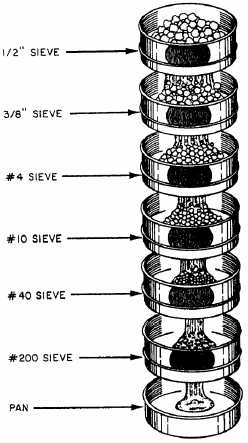

Figure 5-3.-Sieve sizes.

Limestone. Limestone is widely used

for road surfacing, in concrete, and for

l i m e .

Gneiss.

Most

varieties

of

gneiss

have good strength and durability and make

good road aggregates.

Quartzite.

Quartzite

is

both

hard

and durable. Because of these qualities,

it is an excellent rock for construction,

although it is often difficult to quarry.

Marble. The texture and color of

marble

make

it

very

desirable

for

dimension stone, and it can be used for

base course or aggregate material.

Sieve Analysis

Soil

is

composed

of

particles

of

various sizes and composition. Figure 5-2

shows the major types of soils. Soil can

be analyzed by size by sifting a dried and

weighed sample through a set of testing

sieves

(fig.

5-3)

and

weighing

the

material retained on each screen. Further

testing

may

be

required

by

the

specifications for the product you need to

produce.

These

tests

are

normally

performed by the soil laboratory in the

engineering department of the battalion.

Soil is classified according to the

particle size, such as coarse aggregate,

fine

aggregate,

and

mineral

filler.

The

maximum

size

of

the

aggregate

varies,

depending

upon

the

construction

specifications.

Particle

size

is

defined

by passing a soil mass through several

sieves with different sized openings (fig.

5-3).

Particles that pass through a given

sieve are said to be passing that sieve

size. Particles that fail to pass through

a given sieve are said to be retained on

that

sieve.

The

sieve

permits

particles

smaller than the opening to fall through

and retains the larger particles on the

sieve. When you use sieves with screen

openings of different sizes, the soil can

be separated into particle groups based on

size.

A weighted sample of aggregate is

placed in the top sieve, and the entire

set

of

sieves

(largest

on

the

top,

smallest on the bottom) is vibrated either

by hand or mechanically. The individual

weights are calculated as a percentage of

the

total

weight,

as

shown

in

the

following example: Assume we take 3,000

grams of soil mass and determine how much

aggregate passes each sieve.

Aggregate

passing

1/2-inch

sieve and retained on

3/8-inch sieve = 720 grams = 24%

Aggregate

passing

3/8-inch

sieve and retained on No. 4

sieve

=

600

grams

=

20%

Aggregate passing No. 4

sieve and retained on

No. 10 sieve = 450 grams = 15%

Aggregate passing No. 10

sieve and retained on

No. 40 sieve = 570 grams = 19%

Aggregate passing No. 40

sieve and retained on

No. 200 sieve = 420 grams = 14%

Aggregate

passing

No. 200 sieve = 240 grams = 8%

3,000 grams = 100%

The above percentages are one way of

expressing the gradation of a sample of

aggregate.

5-5