load

stockpiled

material

into

overhead

hoppers and trucks.

The production of any pit material

that

requires

crushing

and

screening

depends on the capacity of the processing

equipment used.

QUARRY OPERATIONS

Quarrying

involves

not

only

extraction

of

material

(rock)

but

also

crushing

and

screening

that

makes

the

rock

suitable

for

use

as

construction

material.

Quarry Terminology

Figure 5-10 shows the names of

various

quarry

features.

Overburden

is

the

waste

material

that

often

overlies

pit

or

quarry

sites.

Deposits

within

the waste materials are called spoil and

must

be

removed

before

excavation

of

the

construction

materials

lying

below.

Overburden

refers

to

loose

material

but

locally

it

may

include

solid

rock

lying

above

the

desired

material.

Burden

is

the

construction

material on the face of a quarry. The

floor of the quarry is the inside bottom

surface that marks the lower limit of

excavation.

Often

quarries

contain

one

or more working floors at various levels

above the final quarry floor. A quarry

wall is a more or less vertical surface

that

marks

the

lateral

limit

of

excavation. The face of a quarry is a

rock

surface

(usually

vertical)

from

which rock is to be excavated. The top

of the face is called the crest, and the

bottom is called the toe. A bench is a

steplike

mass

of

rock

behind

a

face

and below a working floor, Notice that

each bench has a face, toe, and crest.

Quarry Development

The

layout

of

a

quarry

should

provide a gravity flow of material from

the face to the crusher, from the crusher

to the storage bin, and from the bin to

the hauling equipment, as illustrated in

figure 5-11. A quarry laid out in this

manner assures that a maximum quantity of

rock can be processed with a minimum of

labor and equipment. In quarries laid out

on

the

gravity-flow

principle,

the

drainage

problem

is

practically

eliminated.

Military

quarries

are

generally

of

the

open-face

type

with

the

vertical

surface of the rock exposed. Depending

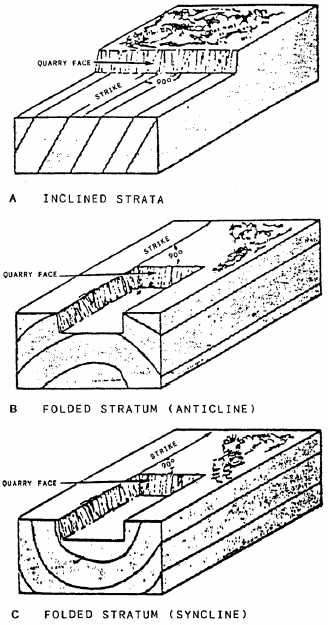

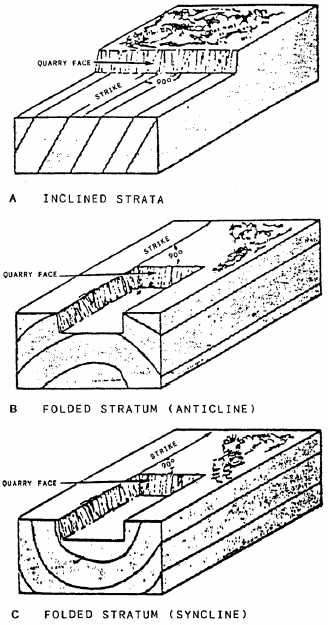

Figure 5-12.-Determining the direction of the

quarry face.

upon local conditions, they may be developed

by the single- or multiple-bench method.

Where the rock face is not exposed,

core samples should be taken in a grid

pattern so rock formations can be plotted,

and the lay of the strata, the quality and

quantity of the deposit, and depth of

overburden can be determined. Should a

rock

formation

be

jointed

or

stratified,

the layout of the quarry is determined by

the

strike

(direction)

of

the

formation;

that is, the face of the quarry must be

directed

at

right

angles

to

the

strike

(fig.

5-12).

This

ensures

a

vertical

or

near vertical face with less chance of

undercutting

the

face

and

creating

a

dangerous overhang.

5-13