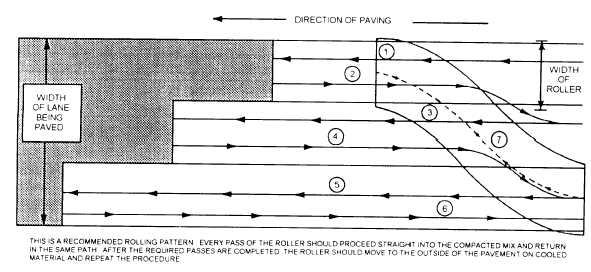

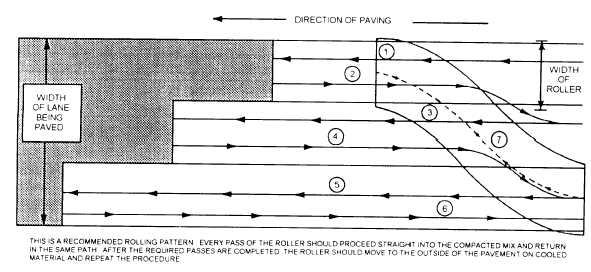

Figure 11-52.—Correct rolling pattern.

steel-tired rollers is shown in figure 11-52. The rolling

operation should start from the edge of the hot mat on

the low side with the roller moving forward as close

behind the paver as possible. The second movement of

the roller should be reversed in the same path until the

roller has reached previously compacted material. At

this point align the roller for pass number three, again

staying as close as possible behind the paver. The fourth

movement is a reversal of the third path and a repetition

of the third operation. After the entire width of the hot

mix has been rolled in this fashion, you should swing

the roller back to the low side and repeat the process.

With this pattern, on each forward pass the roller only

needs to overlap the previous rolled area by 3 to 4 inches.

For thick lifts (a lift of 4 inches or more compacted

thickness), the rolling process should start 12 to 15

inches from the lower unsupported edge and progress

towards the center portion of the hot mix. The

uncompacted edge provides initial confinement during

the first pass, thus minimizing lateral movement of the

hot mix. After the central portion of the hot mix has been

rolled and compacted, the compacted portion of the hot

mix will support the roller and allow the edge to be

compacted without lateral movement.

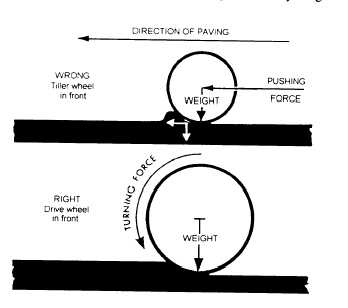

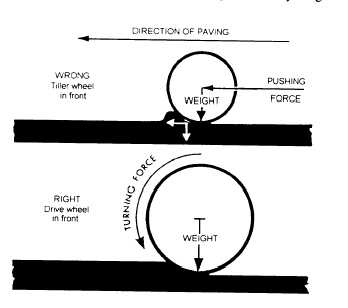

When using steel-wheeled rollers, the operation

should always progress with the drive wheel forward in

the direction of travel. This is especially important in

breakdown rolling. A primary reason that breakdown

rolling should be done with the drive wheel in the

direction of travel is that there is a more direct vertical

load applied by this wheel than by the tiller wheel

(fig. 11-53).

If the breakdown pass of the roller is made with the

tiller wheel forward, the pushing force and the weight

arc slightly ahead of the downward vertical force,

causing material to push up in front of the wheel. The

greater weight of the drive wheel produces the

compaction, while the turning force tends to tuck the hot

mix under the front of the wheel.

There are cxceptions to rolling with the drive wheel

forward. They usually occur when superelevations are

being constructed or if the grade on which the asphalt

mix is being placed is excessive. The exception occurs

when, due to these high grades, the drive wheel of the

roller begins to chatter on the hot mat, causing

displacement of the hot mix resulting with a very rough

Figure 11-53.—Forces acting when tiller wheel or drive wheel

is forward.

11-28