Figure 1-31.—Blower air intake system.

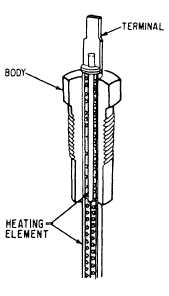

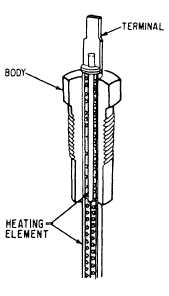

Figure 1-30.-Glow plug.

GLOW PLUGS.— Glow plugs (fig. 1-30) and the

injection nozzle are installed in the precombustion

chamber of the cylinder head. The glow plug is turned

on when you turn on the ignition switch. On some equip-

ment a light on the dashboard signals that the glow plug

is cycling which signals you to wait between 15 to 30

seconds before cranking the engine. The heat, created

by electrical resistance in the glow plug, heats the fuel

and air mixture. The heat generated by the glow plug and

the heat generated by compression allow the fuel to ignite.

AIR INDUCTION SYSTEMS

The function of an air intake system is to supply the

correct amount of air needed to increase the combustion

and the efficiency of an engine. On a diesel engine, the

air intake system cleans the intake air, silences the intake

noise, furnishes air for supercharging, and supplies

scavenged air in two-stroke engines.

The three major components of the air induction

system are blowers, turbochargers, and superchargers.

They may be of the centrifugal or rotary type, or they

may be gear-driven directly from the engine, belt or

chain-driven, or driven by the flow of exhaust gases

from the engine.

BLOWERS

The scavenging process, used in the two-stroke

cycle diesel engine, is simply a charge of air forced into

the cylinder by the blower. As this charge of air is forced

into the cylinder, all the burnt gases are swept out

through the exhaust valve ports. This air also helps cool

the internal engine parts, particularly the exhaust valves.

1-22

The blower shown in figure 1-31 provides the

forced-air induction for the scavenging process. Two

rotors are closely fitted in a housing that is bolted to the

engine. The rotor lobes provide continuous and uniform

displacement of air as the rotors revolve. Blower rotors

either have two lobes or three lobes, depending on the

type.

TURBOCHARGERS

The four-stroke cycle engine uses two methods of

air induction: naturally aspirated and turbo charged. The

naturally aspirated system depends on atmospheric

pressure to keep a constant supply of air in the intake

manifold. The turbocharger is designed to force air into

the cylinder and aid in scavenging the exhaust gases.

The turbocharger differs from the blower in that the

turbocharger uses the energy of exhaust gases to drive

a turbine wheel (fig. 1-32).

The hot exhaust gases from the engine go through

the exhaust inlet, across the turbine wheel, and out the

exhaust outlet. The force of the exhaust turns the turbine

wheel and shaft. This action rotates the compressor

wheel (impeller) that is attached to the opposite end of

the turbine shaft. As the impeller rotates, it draws air into

the housing. The air is then compressed and forced into

the intake manifold.

SUPERCHARGERS

Superchargers are engine-driven air pumps that

force the air and fuel mixture into the engine. They are

made in three basic configurations: centrifugal, Roots,

and vane.