After the base course has passed the compaction

test, prime the hole with a light application of asphalt,

which can either be sprayed or brushed on. The prime

material must be thin enough so that it can be applied

lightly.

NOTE: An excess of asphalt prime coat will flush

into the patch mix and causes bleeding.

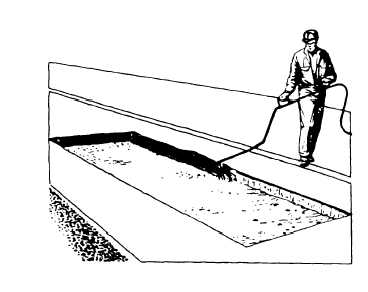

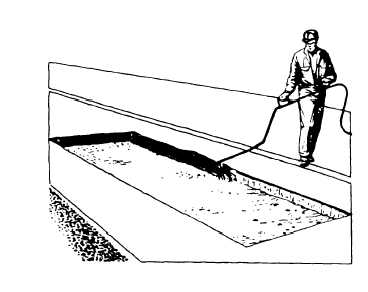

The final step in the preparation of the hole is to

apply a tack coat to the vertical faces, as shown in figure

16-26.

Bituminous Materials Replacement

The first step in the replacement of the paving

materials is to obtain a sufficient quantity of material to

complete the project. Use a hot mix if possible because

it is stronger and lasts much longer.

To allow for

compaction when using a hot mix, you should overfill

the area approximately 40 percent of the pavement

thickness. When a cold mix is used, it should be spread

and rolled in layers with each layer not to exceed 1 1/2

times the maximum aggregate size in the mix. When

cold mix is spread, keep the material as level as possible

to prevent segregation. Both hot and cold mixes can be

spread by grader, by paver, or by hand, depending on the

size of the repair.

Compaction of bituminous materials is done with

steel-wheel rollers and pneumatic-tired rollers on larger

areas, or with vibrator tampers, vibratory patch rollers,

and hand tampers on smaller areas. Compaction is an

important part of the patching operation. The rolling

operation on hot mix should begin immediately after the

material is placed. Cold mix should be rolled after

Figure 16-26.-Tack coat application to the vertical faces.

16-22

proper aeration of the material. The edges of the patch

should be rolled first. This seals the edges and prevents

the material from dishing out and water from

infiltrating. When cold mix is used, the patch may have

a porous surface and require waterproofing. This can

be done by applying a sand seal or by applying a thin

layer of portland cement and tamping it in.

Obtaining a smooth riding surface requires care.

Too many patches are built as mounds that result as

bumps in the road A straightedge should be used as a

guide to finish the patch. The patch should not be lower

than the rest of the pavement. Instead, it should be level

with or one-eighth inch higher than the surrounding

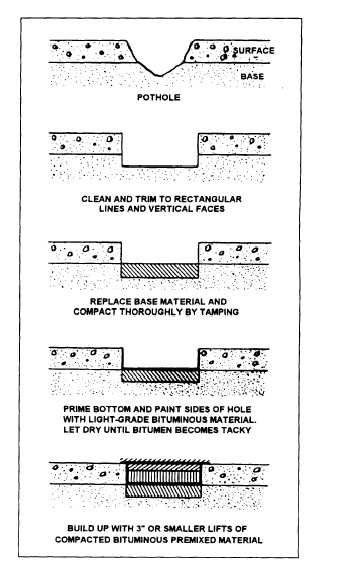

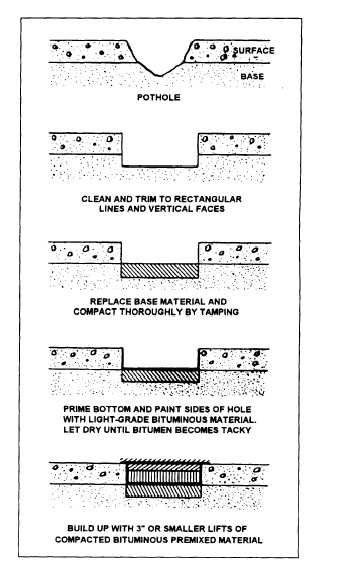

area. Figure 16-27 shows the steps in patching a

pothole.

Figure 16-27.-Steps in patching a pothole.