forth laterally with a grader before being spread and

compacted. This action speeds up setting or curing.

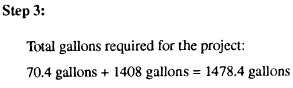

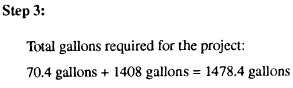

Always round your answer to the next higher

number. In this case, 1478.4 is rounded to 1479 gallons.

TYPES OF ASPHALT PAVEMENT

CONSTRUCTION

Two major types of asphalt pavement construction

are in use today: plant mix construction (so-called

because the mixture is prepared in a central mixing

plant) and mixed-in-place construction (so-called

because the mixture is mixed on the area to be paved).

PLANT MIX CONSTRUCTION

L =

Asphalt-paving mixtures, prepared in a asphalt

mixing plant, are known as plant mixes. Plant mix

asphalt concrete is considered the highest quality plant

mix. It consists of well-graded, high-quality aggregate

and asphalt cement.

The asphalt and aggregate are

heated separately from 250°F to 325°F, carefully

measured and proportioned, then mixed until the

aggregate particles are coated with asphalt. The hot

mixture, kept hot during transit, is hauled to the

construction site where it is spread on the roadway with

an asphalt-paving machine. The smooth layer from the

paver is compacted by rollers to proper density before

the asphalt cools.

W =

D =

146 =

Asphalt concrete is but one of a variety of

hot-asphalt plant mixes.

Other mixes, such as sand

asphalt and coarse-graded mixes, are prepared and

placed in a similar manner; however, each has one

common ingredient, which is asphalt cement.

Asphalt mixes, containing emulsified or cutback

asphalt, may also be prepared in asphalt mixing plants.

The aggregate may be partially dried and heated or

mixed as it is withdrawn from the stockpile. These

mixes are usually refered to as cold mixes, even though

heated aggregate may have been used in the mixing

WF =

2,000 =

process.

Both asphalt mixtures, made with emulsified

asphalt and some cutback asphalts, can be spread and

compacted on the roadway while quite cool. Such

mixtures are called cold-laid asphalt plant mixes

They are hauled and placed in normal warm weather

temperatures. These mixtures, after being placed on the

roadway, are sometimes processed or worked back and

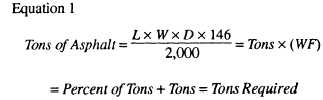

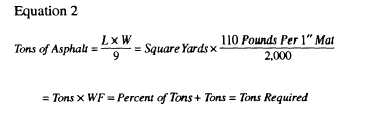

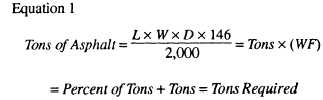

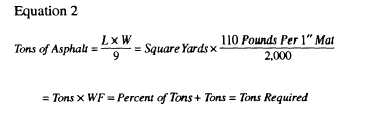

Compute Plant-Mix Materials

Several methods are used to calculate the amount of

hot-mix material, required for paving projects; however,

when the weight of a hot mix per square yard or cubic

foot is not known, two equations are used in the NCF to

compute the number of tons of asphalt, required for a

project. These equations are as follows:

length of project in feet.

width of project in feet.

depth or thickness of compacted mat. You

must change inches into feet by dividing the

number of inches by 12 (inches in 1 foot).

For paver screed height, add 1/8 inch for

each inch of the mat to be paved. (Example:

For a 2-inch mat, two blocks of wood 2 1/4

inches thick will be required to set under the

screed.) The blocks must be thicker than

the finished compacted mat to allow for

additional compaction by rollers.

This number represents the approximate

weight of 1 cubic foot of compacted

hot-mix asphalt.

This number can vary

from 140 to 160 pounds; however,

146 pounds equals the 110 pounds per

square yard per l-inch depth of asphalt used

in the second equation for figuring tons

require for asphalt. (See table 16-2.)

Waste factor equals 5% or .05, or 10% or

.10, depending on the experience of the

screed operators and handwork required on

the project.

2,000 pounds is equal to one ton; therefore,

you must divide the total weight of material

by 2,000, giving tons required.

16-9