Notice that figure 12-3 does not indicate the

physical location of the individual components

with respect to each other in the system. For

example, the 3/4-inch, solenoid-operated, 4-way

valve (10) is not necessarily located directly above

the relief valve (26). The diagram does indicate,

however, that the 4-way valve is located in the

working line, between the variable-displacement

pump and the 1-inch rotary selector valve, and

that the valve directs fluid to and from the rotary

actuator.

Combination Diagrams

A combination drawing uses a combination

of graphic, cutaway, and pictorial symbols. This

drawing also includes all interconnecting piping.

FLUID POWER SYSTEMS

A fluid power system in which the fluid in the

system remains pressurized from the pump (or

regulator) to the directional control valve while

the pump is operating is referred to as a closed-

center system. In this type of system, any number

of subsystems may be incorporated, with a

separate directional control valve for each

subsystem. The directional control valves are

arranged in parallel so that system pressure acts

equally on all control valves.

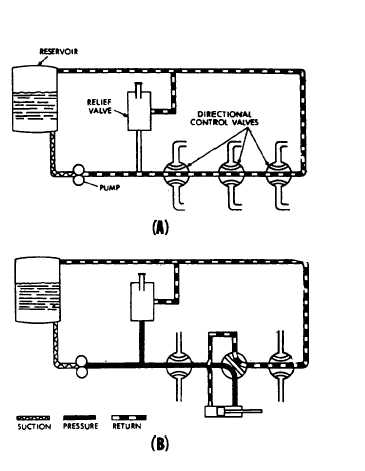

Another type of system that is sometimes used

in hydraulically operated equipment is the open-

center system. An open-center system has fluid

flow but no internal pressure when the actuating

mechanisms are idle. The pump circulates the fluid

from the reservoir, through the directional control

valves, and back to the reservoir. (See fig. 12-4,

view A.) Like the closed-center system, the open-

center system may have any number of subsystems,

with a directional control valve for each subsystem.

Unlike the closed-center system, the directional

control valves of an open-center system are always

connected in series with each other, an arrange-

ment in which the system pressure line goes

through each directional control valve. Fluid is

always allowed free passage through each control

valve and back to the reservoir until one of the con-

trol valves is positioned to operate a mechanism.

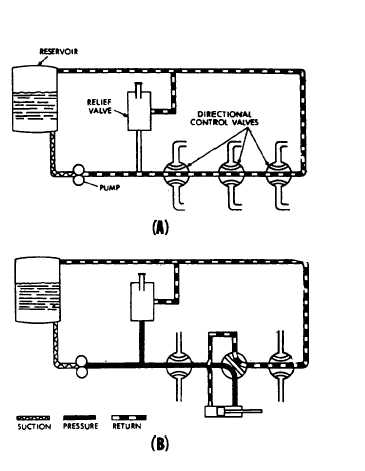

When one of the directional control valves is

positioned to operate an actuating device, as

shown in view B of figure 12-4, fluid is directed

from the pump through one of the working lines

to the actuator. With the control valve in this

position, the flow of fluid through the valve to

the reservoir is blocked. Thus, the pressure builds

up in the system and moves the piston of the

Figure 12-4.—Open-center hydraulic system.

actuating cylinder. The fluid from the other end

of the actuator returns to the control valve

through the opposite working line and flows back

to the reservoir.

Several different types of directional control

valves are used in the open-center system. One

type is the manually engaged and manually

disengaged. After this type of valve is manually

moved to the operating position and the actuating

mechanism reaches the end of its operating cycle,

pump output continues until the system relief

valve setting is reached. The relief valve then

unseats and allows the fluid to flow back to the

reservoir. The system pressure remains at the

pressure setting of the relief valve until the

directional control valve is manually returned to

the neutral position. This action reopens the

open-center flow and allows the system pressure

to drop to line resistance pressure.

Another type of open-center directional

control valve is manually engaged and pressure

disengaged. This type of valve is similar to the

valve discussed in the preceding paragraph;

however, when the actuating mechanism reaches

the end of its cycle and the pressure continues to

12-5