part of the material in the opposite direction. The

TORSIONAL STRESS

action of a pair of scissors is an example of shear

forces and shear stresses. The scissors apply shear

Torsional stresses develop in a material when

forces, and the material being cut resists the shear

external forces are applied in such a way that they tend

forces by its internal shear stresses. Forces tending to

to produce rotation. A ship's shaft, for example,

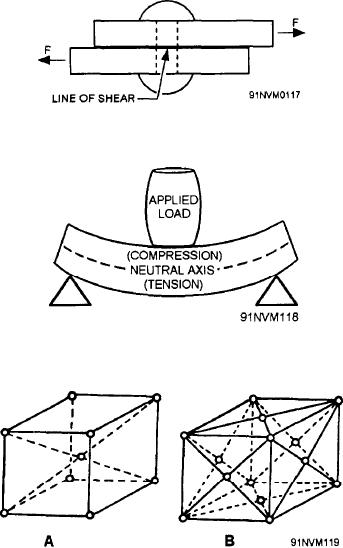

produce shear in a rivet are illustrated in figure 6-3.

rotates when the external applied forces are greater

Shear stresses are not shown, since they are

than the internal torsional stresses developed in the

considerably more complex than tension stresses and

shaft. Torsional stress is primarily a special form of

compression stresses.

shear stress, although it may also involve some

compression stress and some tension stress.

BENDING STRESS

INTERNAL STRUCTURE OF METALS

Bending stresses develop when a material is

subjected to external forces that tend to bend it. When

The atoms in all solid metals are arranged in some

a load is applied to a beam, for example, as shown in

definite geometric (or crystallographic) pattern. The

figure 6-4, the upper surface is in compression and the

smallest grouping of atoms that has the complete

lower surface is in tension. The NEUTRAL AXIS,

symmetrical arrangement of the crystal is called a unit

indicated by the broken line in figure 6-4, is neither in

cell. The regular arrangement of these atoms is called

compression nor in tension.

a space lattice. A unit cell is much too small to be seen.

When a great many unit cells are combined, however,

they form a visible crystal that has the same geometric

structure as the unit cell.

A number of different geometrical arrangements

of atoms are possible, but most metals have space

lattices that are basically shaped like cubes, tetragons,

or hexagons. Figure 6-5 shows the body-centered

Figure 6-3.--Shearing forces applied to a rivet.

cubic and face-centered cubic space lattices.

How do crystals form? When the metal is in the

liquid state, the atoms move freely and are not

arranged in any orderly fashion. When the metal

begins to cool, however, the atoms move more and

more slowly. When the freezing (solidifying)

temperature of the metal is reached, the atoms begin

to form unit cells of the type characteristic of the

particular metal. In this crystallization process, the

atoms give up energy in the form of heat. As this

energy flows from the metal, other atoms form around

Figure 6-4.--Load applied to a beam.

each of the original unit cells in a definite pattern. This

definite and repeating pattern upon solidification is

called a space lattice. Eventually all of the metal is

changed from the liquid state, in which the atoms are

moving freely, to the solid state, in which the atoms

are arranged in a definite, orderly pattern. At this

point, we say that the metal has completely solidified

or frozen.

If crystallization could proceed without any

the external form of the internal space lattice. As a

rule, however, the space lattices do not all line up

Figure 6-5.--Crystal structure of iron. A. Body-centered cubic,

perfectly with each other; this means that the growth

9-atom space lattice. B. Face-centered cubic, 14-atom space

of some crystals interferes with the growth of others.

lattice.

6-4