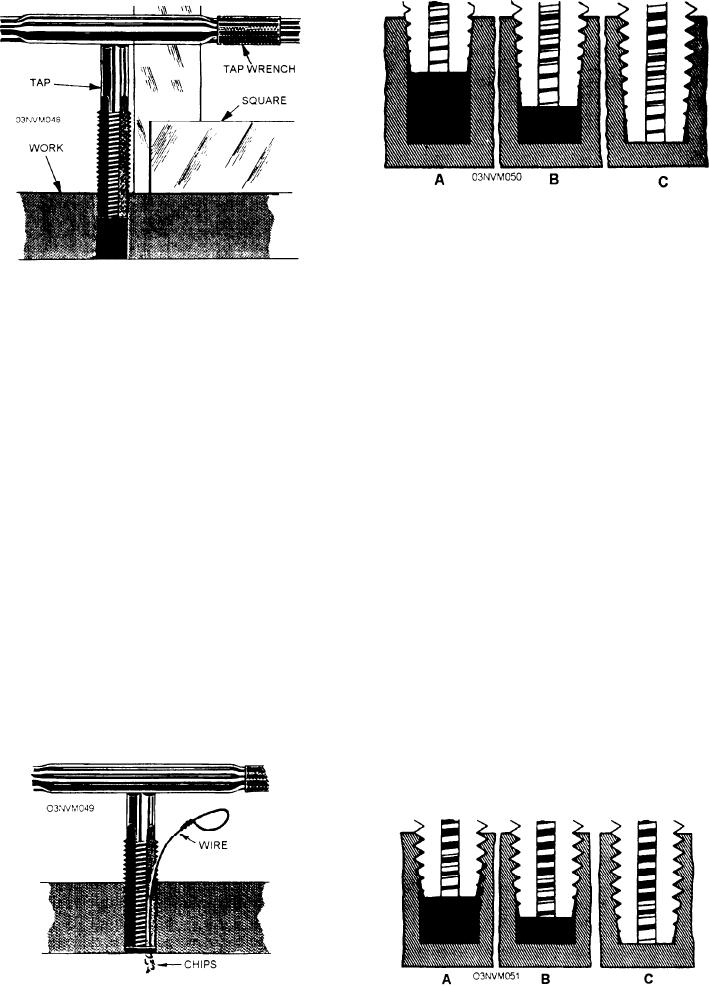

Figure 5-50.--Tapping a blind hole with a taper tap.

immediately. Back the tap up a quarter turn to break

Figure 5-48.--Using a square to ascertain a tap is square with

the chips, clean them out of the flutes with a wire (as

the work.

shown in fig. 5-49), add some more lubricant, and

continue tapping. When the tap has cut threads

through the hole, the tap will turn with no resistance.

Cutting Machine Threads With Taps

To tap a blind hole, start with the taper tap. For a

blind hole you will need all three types--the taper,

Mineral lard oil, applied with a small brush, is

plug, and bottoming taps. Be sure they are the size and

highly recommended as a lubricant when tapping in

thread series you need, and that the tap hole is the size

steel. When using this lubricant, tighten the tap in the

called for by the working drawing and table 5-2.

tap wrench and apply the lubricant to the tap. Start the

tap carefully with its axis on the center line of the hole.

Begin with the taper tap. Handle it as described

The tap must be square with the surface of the work,

earlier. Figure 5-50, view A, shows the taper tap just

as shown in figure 5-48.

starting to cut. In figure 5-50, view B, it has cut a little

farther. In figure 5-50, view C, it has bottomed in the

To continue tapping, turn the tap forward two

hole after having cut several full threads near the top

quarter turns, back it up a quarter turn to break the

of the hole. This completes the work to be done with

chips, and then turn forward again to take up the slack.

the taper tap.

Continue this sequence until the required threads are

cut. After you cut for the first 2 or 3 full turns, you no

In figure 5-51, view A, the plug tap has entered

longer have to exert downward pressure on the

the few full threads cut by the taper tap. In figure 5-51,

wrench. You can tell by the feel that the tap is cutting

view B, it has continued these threads a little farther

as you turn it. Don't permit chips to clog the flutes or

down into the hole. In figure 5-51, view C, it has

they will prevent the tap from turning. When the tap

bottomed in the hole. This is all the work that you can

won't turn and you notice a springy feeling, stop trying

do with the plug tap. It has cut full threads about

halfway down the tap hole before bottoming.

Figure 5-49.--Using a wire to clear chips from the flute of a

tap.

Figure 5-51.--Tapping a blind hole with a plug tap.

5-28