have the typical shape of the space lattice, it is custom-

In other words, space lattices that are not oriented in

ary to call each visible unit a grain rather than a crystal.

approximately the same way cannot join each other.

The areas between adjacent grains are shown as grain

As a result, the crystallization process usually results

boundaries. The grain boundary material has somewhat

in the growth of many small crystals rather than one

different properties than the actual grains or crystals;

large one. In any given piece of solid metal, the size

this is partly because the space lattices are distorted at

of the crystals will vary. The larger ones are the result

the grain boundaries and partly because the process of

of the combination of a great many space lattices that

crystallization tends to push impurities out of the crys-

happened to line up in such a way that they could join

tals and into the grain boundaries.

each other.

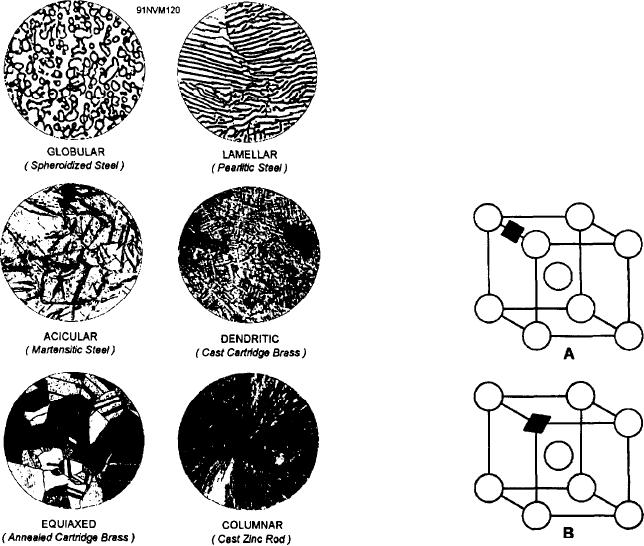

The term grain structure refers to the crystalline

Because the crystals interfere with each other as

structure of the metal, often with particular reference to

they grow, a piece of metal in cross section may show

the shape and size of the grains. Figure 6-6 illustrates

very few characteristic crystal shapes. Note, however,

several types of gram structure, as seen under a micro-

that the metal is still considered crystalline even if the

scope. The size of the grains depends upon a number of

crystalline forms are distorted. The crystals are there,

factors, including the nature of the metal, the tempera-

but they are not usually perfect in shape.

ture to which it is heated, the length of time it is held at

When a metal crystallizes in such a way that the

a specified temperature, and the rate at which it is cooled

crystals are not perfectly formed and therefore do not

from a liquid to the solid state. In general, the quicker a

metal solidifies, the smaller the grain will be. The size

of grain structure desired for any particular application

depends upon the purpose for which the metal is to be

used.

In alloys, the internal structure may be in the form

of crystals of pure metals, solid solutions, intermetallic

compounds, mechanical mixtures, or some combina-

tion of these structures.

In a solid solution, the elements are completely

dissolved in each other, with the atoms of each

element fitting into and forming part of the space

lattice of the other element. Figure 6-7 illustrates two

Figure 6-7.--Space lattices of two forms of solid solution. A.

Atoms of one element fit between atoms of another element.

B. Atoms of one element replace atoms of another element.

Figure 6-6.--Grain structure in metals.

6-5