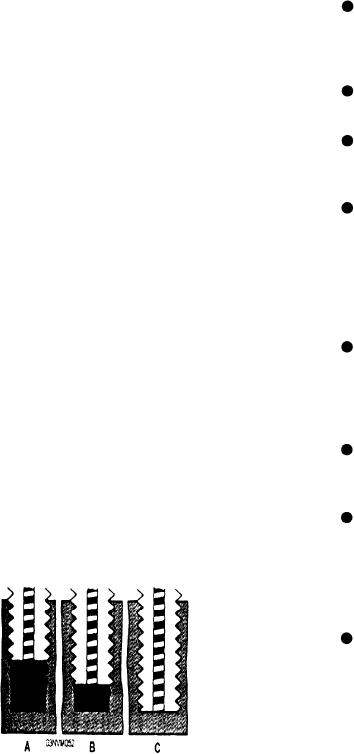

In figure 5-52, the bottoming tap has been substi-

SAFETY PRECAUTIONS

tuted for the plug tap. In figure 5-52, view A, it has been

Before using any machine tool, you must be famil-

run down the full threads cut by the plug tap and is ready

iar with all safety precautions pertaining to its operation.

to cut more full threads. In figure 5-52, view B, it has

Carelessness around any moving machinery is ex-

cut a few more threads, and in figure 5-52, view C, it

tremely dangerous. When moving machinery is

has bottomed in the hole. The blind hole has now been

equipped with sharp cutting tools, the dangers are

completely tapped.

greatly increased. The following list includes some of

Because these threads are being tapped in a blind

the more general safety precautions for machine tools.

hole, you must remove chips differently. To remove

Specific safety precautions should be posted in plain

chips, back the tap completely out of the hole very

sight by every machine.

frequently, invert the stock, if possible, and jar out the

chips or work them out of the hole with a wire while the

Do not lean against any machine that is in

stock is in the inverted position.

motion. Keep clear of all gears, belts, and

Chip removal in tapping blind holes is much more

other moving parts. Never remove the guards

difficult to do and is very important because chips will

from any part of an operating machine.

fal1 ahead of the tap through the flutes and accumulate

Never start a machine unless you are thor-

in the bottom of the blind hole. Until these chips are

oughly familiar with its operation.

removed, none of the three taps can complete its work.

In tapping blind holes, alternate with tapping and chip

Do not attempt to clean, adjust, or repair a

removal until each of the three taps bottom in the blind

machine while it is in motion. NEVER attempt

hole.

When you have finished using the three taps, brush

PROTECT YOUR EYES. Do not hold your

the chips out of their teeth, oil them well with lubricat-

head too close to the cutting tool. Flying bits

ing oil, wipe off the surplus oil, and replace them in the

of metal or scale may get into your eyes.

threading set.

Always wear goggles when there is any dan-

ger of flying particles getting in your eyes--

for example, when using a grinding or drilling

INSTALLED MACHINE TOOLS

machine.

The Navy furnishes modern equipment to help

PROTECT YOUR HEARING. Always wear

you perform your duties. This section introduces you

appropriate hearing protection. Either audio

to some of the most common machine tools found in

headsets or ear plugs will filter the noise from

workshops that you should be familiar with. A

running machinery. Prolonged exposure may

damage your hearing.

machine tool is a power-driven machine that holds the

material and cutting tool and brings them together so

Keep your fingers away from the cutting

the material is drilled, cut, shaved, or ground.

edges when the machine is in operation. Oth-

erwise, you could lose some fingers.

The machine tools described in this chapter are

found in most well-equipped shops. Other machine

Do not wear gloves or loosely hanging

tools for specific types of work will be described in their

clothes. They can be caught by moving parts

appropriate chapter of this training manual.

of the shop machinery and cause serious inju-

ries. Keep your sleeves rolled up tightly above

the elbows. Do not wear neckties or loose

neckerchiefs.

In all machine work, stress SAFETY first,

ACCURACY second, and SPEED last. Ex-

cessive speed is both dangerous and ineffi-

cient.

METAL-CUTTING SAWS

Metal-cutting saws are standard equipment in re-

Figure 5-52.--Finish tapping a blind hole with a bottoming

pair facilities. They are used for nonprecision cutting of

tap.

5-29