Manufacturer's Record.--The sixth section of

VITRIFIED bonded wheels are designated by the

the grinding wheel marking is the manufacturer's

letter V. They are not affected by oil, acid, or water.

record. This may be a letter or number, or both. It is

Vitrified bonded wheels are strong and porous, and

used by the manufacturer to designate bond

rapid temperature changes have little or no effect on

modifications or wheel characteristics.

them. Do not run vitrified wheels faster than 6,500

surface feet per minute (sfpm).

GRINDING WHEEL SELECTION

SILICATE bonded wheels are designated by the

AND USE

letter S. Silicate bonded wheels are used mainly on

large, slow rpm machines where a cooler cutting action

You should select a grinding wheel that has the

is desired. Silicate bonded wheels are softer than vitri-

proper abrasive, grain, grade, and bond for the job.

fied wheels, and they release the grains more readily.

You should base your selection on such factors as the

Like the vitrified bonded wheel, do not run this wheel

physical properties of the material to be ground, the

in excess of 6,500 sfpm.

amount of stock to be removed (depth of cut), the

RUBBER bonded wheels are designated by the

wheel speed and work speed, and the finish required.

letter R. These wheels are strong and elastic and they

To grind carbon and alloy steel, high-speed steel,

are used as thin cutoff wheels. These wheels are used

cast alloys, and malleable iron, you probably should

extensively for regulating wheels on centerless grind-

use an aluminum oxide abrasive. A silicon carbide

ers. Rubber bonded wheels produce a high finish and

can be run at speeds up to 16,000 sfpm.

abrasive is most suitable for grinding nonferrous

metals, nonmetallic materials, and cemented carbides.

RESINOID bonded wheels are designated by the

letter B. These wheels are shock resistant and strong and

Generally, you'll choose coarser-grain wheels to

are used for rough grinding and cutoff wheels. Like

grind softer and more ductile the materials. Also use

rubber bonded wheels, you can run these wheels at

coarser-grain wheels to remove a large amount of

speeds up to 16,000 sfpm.

material (except on very hard materials). If a good

SHELLAC bonded wheels are designated by the

finish is required, a fine grain wheel should be used.

letter E. These wheels give a high finish and have a cool

For soft materials, small depth of cut, or high-work

cutting action when used as cutoff wheels. Shellac

speed, use a soft grade wheel. If the machine you are

bonded wheels can be run at speeds up to 12,500 sfpm.

using is worn, you may need to use a harder grade

wheel to offset the effects of that wear. You also can

OXYCHLORIDE bonded wheels are designated

use a harder grade wheel if you use a coolant with it.

by the letter O. Do not run these wheels at speeds

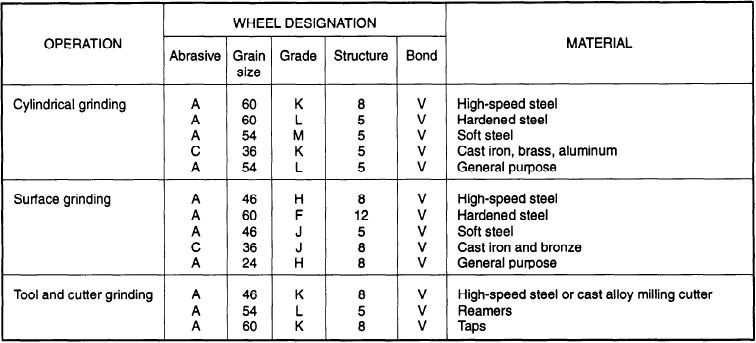

Table 5-3 lists recommended grinding wheels for

greater than 6,500 sfpm.

Table 5-3.--Recommendations for Selecting Grinding Wheels

5-37