-- If a lot of metal is to be removed, use the coarse

wheel to remove most of it.

-- Use a gauge, template, or a sample for compari-

son, unless you are familiar with the exact finished

shape of the article you are grinding.

Grinding Wheels

A grinding wheel is made up of two basic

elements: (1) the abrasive grains and (2) the bending

agent. The abrasive grains may be compared to many

single-point tools embedded in a toolholder of

bonding agent. Each of these grains removes a very

small chip from the material as it makes contact on

each revolution of the grinding wheel.

An ideal cutting tool is one that will sharpen itself

when it becomes dull. This, in effect, is what happens

to the abrasive grains. As the individual grains become

dull, the pressure that is generated on them causes

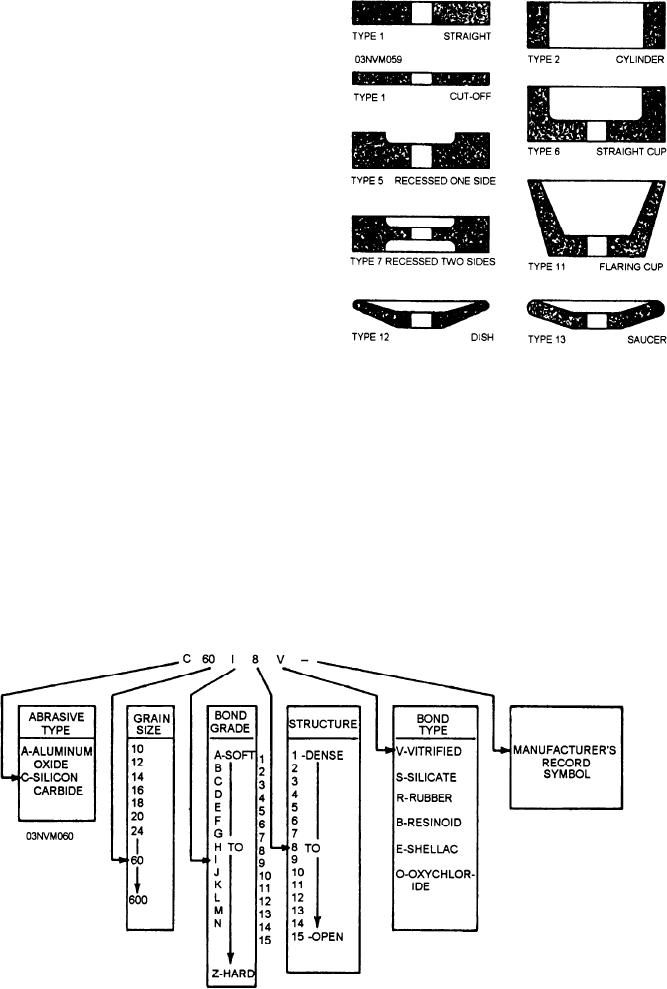

Figure 5-59.--Grinding wheel shapes.

them to fracture and present new sharp cutting edges

to the work. When the grains can fracture no more, the

all manufacturers. The shapes are shown in cross-

pressure becomes too great and they are released from

sectional views. The specific job will dictate the shape

the bond, allowing a new layer of sharp grains to be

of wheel you should use.

presented to the work.

WHEEL MARKINGS AND COMPOSI-

SIZES AND SHAPES.--Grinding wheels come

TION. --Grinding wheel markings are comprised of

in various sizes and shapes. The size of a grinding

six sections, each of which identifies a characteristic

wheel is given in terms of its diameter in inches, the

of the wheel. The six sections are (1) type of abrasive,

diameter of its spindle hole, and the width of its face.

Grinding wheels have too many shapes to list in this

(2) grain size, (3) bond grade, (4) structure, (5) type

manual, however, figure 5-59 shows those used most

of bond, (6) the manufacturer's record symbol. Figure

often. The type numbers are standard and are used by

5-60 shows the standard marking system and possible

Figure 5-60.--Standard marking system for grinding wheels (except diamond).

5-35