Figure 7-12.--Indexing equipment.

The workpiece may be held in a chuck or a collet,

can turn the dividing head spindle one of two ways:

attached to the dividing head spindle, or held between

Do it directly by hand by disengaging the worm and

a live center in the dividing index head and a dead

drawing the plunger back, or by the index crank

center in the footstock. The center of the footstock

through the worm and worm gear.

can be raised or lowered to set up tapered workpieces.

The spindle is set in a swivel block so you can set

The center rest can be used to support long slender

the spindle at any angle from slightly below

work.

horizontal to slightly past vertical. We said earlier

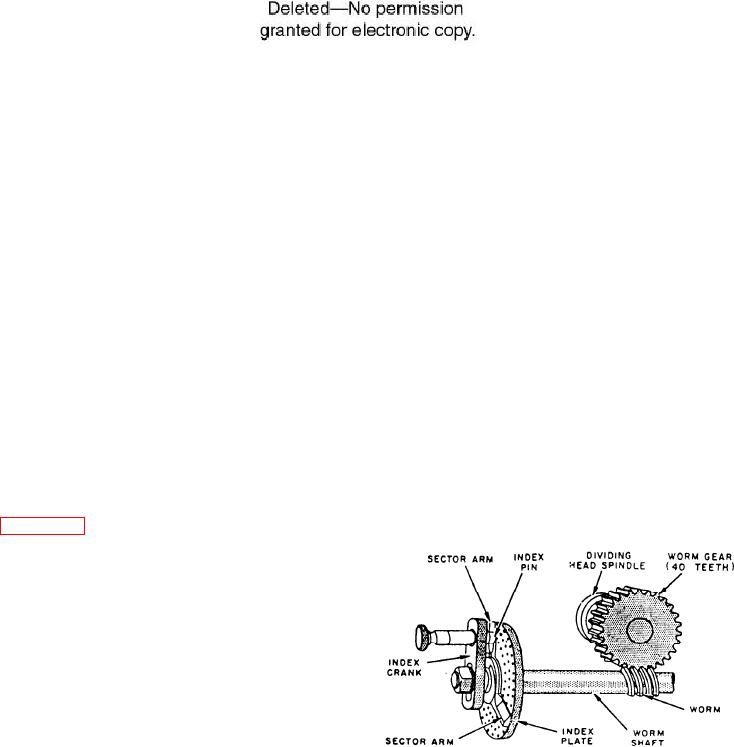

Figure 7-13 shows the internal components of the

dividing head. The ratio between the worm and the

gear is 40 to 1. By turning the worm one turn, you

rotate the spindle 1/40 of a revolution. The index

plate has a series of concentric circles of holes. You

can use these holes to gauge partial turns of the worm

shaft and to turn the spindle accurately in amounts

smaller than 1/40 of a revolution. You can secure the

index plate either to the dividing head housing or to a

rotating shaft and you can adjust the crankpin radially

for use in any circle of holes. You can also set the

sector arms as a guide to span any number of holes in

the index plate to provide a guide to rotate the index

Figure 7-13.--Dividing head mechanism.

crank for partial turns. To rotate the workpiece, you

7-9