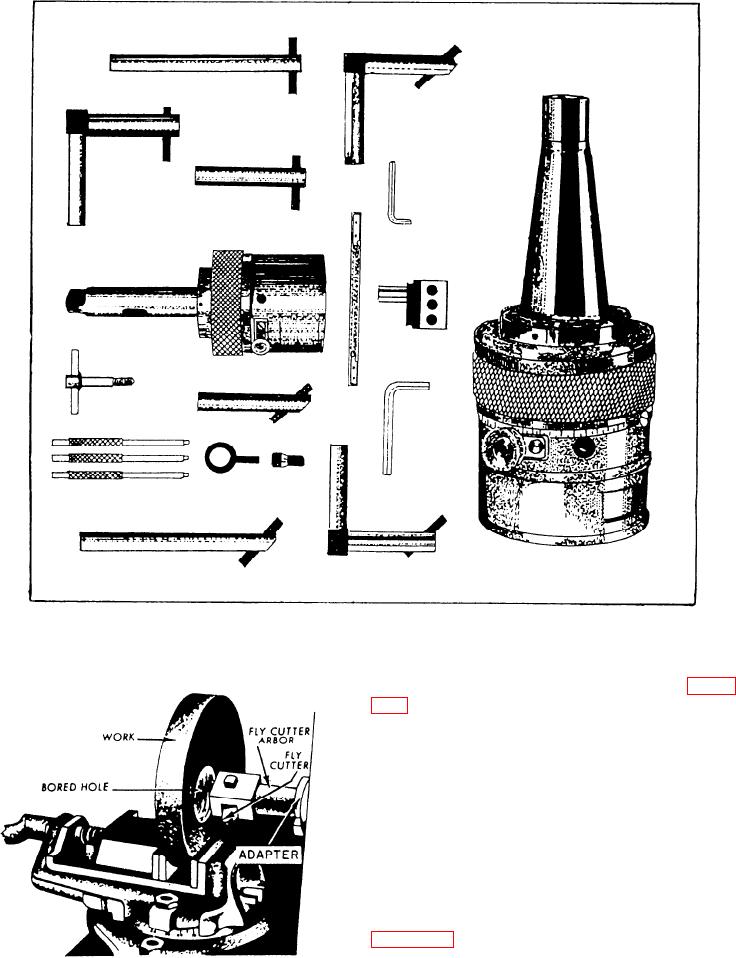

Figure 7-76.--Offset boring head and boring tools.

usually bore holes with an offset boring head. Figure

7-76 shows several views of an offset boring head and

several boring tools. Note that the chuck jaws, which

grip the boring bar, can be adjusted at a right angle to

the spindle axis. This feature lets you accurately

position the boring cutter to bore holes of varying

diameters. This adjustment is more convenient than

adjusting the cutter in the boring bar holder or by

changing boring bars.

Although the boring bars are the same on a

milling machine as on a lathe or drill press, the

manner in which they are held is different. Note in

figure 7-77 that a boring bar holder is not used. The

boring bar is inserted into an adapter and the adapter

is fastened in the hole in the adjustable slide. Power

Figure 7-77.--Boring with a fly cutter.

to drive the boring bar is transmitted directly through

the shank. The elimination of the boring bar holder

7-46