axial-flow

positive-displacement

blower

(Hamilton-Whitfield), the problems of operation and

maintenance are similar.

Some of the troubles in a positive-displacement

blower are similar to those already mentioned in our

discussion of the centrifugal-type blowers. However,

the source of some troubles may be different because of

construction differences.

Positive-displacement blowers have a set of gears

to drive and synchronize the rotation of the rotors. Many

of these blowers are driven by a serrated shaft.

Regardless of construction differences, the basic

problem in both types of blowers is in maintaining the

necessary small clearances. If these clearances are not

maintained, the rotors and the case will be damaged and

the blower will fail to perform its function.

Worn gears are one source of trouble in

positive-displacement blowers. A certain amount of gear

wear is expected, but damage caused by excessively

worn gears indicates improper maintenance procedures.

Whenever you inspect a positive-displacement blower,

record the backlash values, according to PMS. You can

use this record to establish the rate of increase in wear,

to estimate the life of the gears, and to determine when

it will be necessary to replace the gears.

Scored rotor lobes and casing may cause blower

failure. Scoring of blower parts may be caused by worn

gears, improper timing, bearing failure, improper end

clearance, or by foreign matter. Any of these troubles

may be serious enough to cause the rotors to contact and

damage the blower extensively.

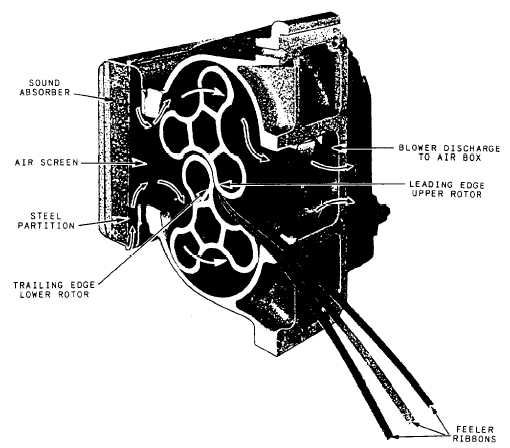

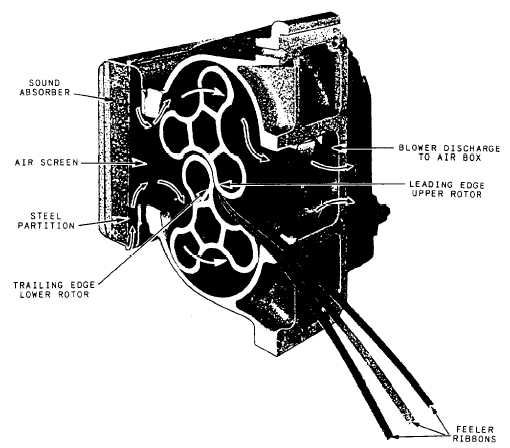

Timing of blower rotors involves both gear backlash

and the clearances between the leading and trailing

edges of the rotor lobes and between rotor lobes and the

casing. You can measure the clearance between these

parts with thickness gauges, as illustrated in figure 3-39.

If the clearances are incorrect, check the backlash of the

drive gear first. Then retime the rotors according to the

method outlined in the manufacturer’s technical

manual.

Failure of serrated blower shafts may be due to

failure to inspect the parts or of improper replacement

of parts. When you inspect serrated shafts, be sure that

they fit snugly and that wear is not excessive. When

Figure 3-39.—Checking clearances of positive-displacement blower lobes.

3-34