The operators of Class B assigned

CESE signs the CB 60 form assuming full

custody of mounted collateral gear. CB 60

forms for Class C mounted collateral gear

on CESE are signed by the yard boss. The

mounted

collateral

gear

should

be

annotated on the daily (rip ticket, and

custody is assumed by the operator who

signs the trip ticket, or the collateral

equipage can be issued and returned to

collateral each time the unit of CESE is

dispatched.

ATTACHMENT CUSTODIAN

Attachments

are

accessories

to

construction

equipment

that

enable

the

basic equipment to perform its function

or

adds

versatility.

Attachments

are

stored on handstands to keep the items

out of sand, mud, and water. Hydraulic

lines

and

fittings

are

sealed

for

protection from dirt and moisture.

Attachment

accessories,

such

as

bucket teeth, sprockets, drum lagging, and

wedges, are placed in boxes or on pallets

and marked for the appropriate equipment.

Wire rope, sheaves, and bolt threads are

lubricated. Nuts and bolts are stored in

their respective holes on the attachments

when possible. Exposed machined surfaces

and open parts are preserved to prevent

oxidation

and

damage.

Storage

is

maintained to ensure attachments belonging

to one USN number are stored together.

The attachment custodian maintains a

card

file

and

log

that

provides

an

accurate inventory of receipts and issues

of attachments, when the attachments were

last lubricated, and any damage incurred

from

one

operation

to

another.

In

addition, the custodian is responsible for

the segregated storage of all attachments

and

their

associated

accessories.

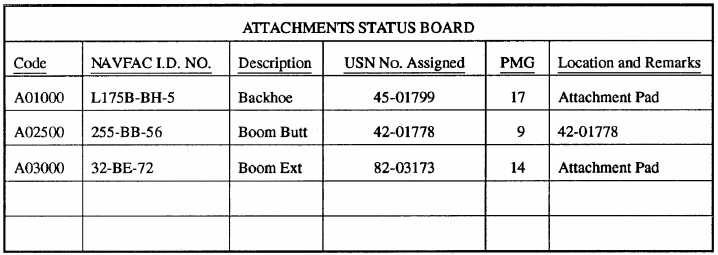

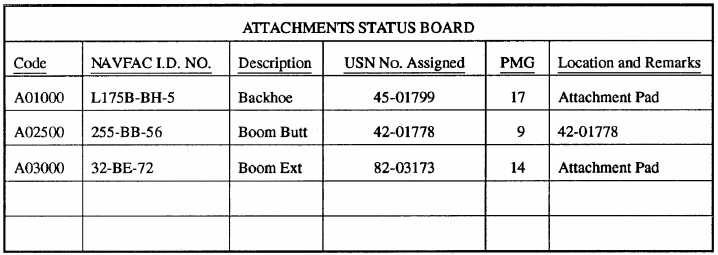

The Attachments Status Board (fig.

1-13)

is

maintained

in

the

dispatcher’s

office by the attachment custodian. The

Attachments

Status

Board

reflects

the

attachment

code,

NAVFAC

identification

number, abbreviated description, the USN

number of the equipment to which the

attachment is assigned, the PM group (same

as

the

equipment

the

attachment

is

assigned), and location and remarks. The

collateral

equipage

custodian

usually

performs

the

duties

of

the

attachment

custodian.

FUEL OPERATIONS

The transportation pool manages all

fuel operations. The Equipment Operator in

charge of fuel operations must be mature,

independent,

and

reliable.

The

abilities

to communicate and to maintain logs are

also required. A poor fuel program results

in needless downtime of equipment and

delays

in

production.

The fuel truck driver reviews the

Equipment Status Board to determine the

location of all CESE. The driver learns

the fuel requirements and function of all

equipment used on construction projects by

communicating

with

the

project

crew

leaders, the assigned Equipment Operator,

and the transportation supervisor.

The

fuel

truck

driver

must

be

knowledgeable of all CESE. The driver must

avoid

fueling

with

the

wrong

fuel

or

filling hydraulic or cooling systems with

fuel.

Maintenance

and

transportation

super-visors

have

fuel

tanks

stenciled

with the words MOGAS or DIESEL to avoid

this problem.

Figure 1-13.—Attachments Status Board.

1-16