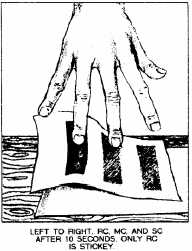

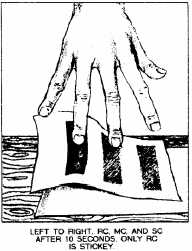

Figure 8-24.–Smear test of asphalt cutback.

Smear Test

The smear test is used to separate

an RC from an MC or SC. The test is

primarily based on the fact that RCs are

cutback with a highly volatile material

(naphtha or gasoline). You can determine

whether a sample is an RC or not by

smearing some of the sample in a thin

layer on a nonabsorbent surface, such as a

piece

of

glazed

paper.

The

volatile

substance evaporates within a few minutes

and the surface becomes so tacky that when

touched,

the

specimen,

paper

and

all,

sticks to your fingers and can be lifted

into the air (fig. 8-24).

Checking the reverse side of the

paper, you will find that the RC did not

penetrate through the paper as MCs or SCs

do. MCs and SCs on smear tests remain

fluid and oily for time periods that vary

from hours to days, depending on the type

and grade of material. If an 800 or 3,000

grade MC or SC is present, they may become

sticky in a few minutes since there is

such a small amount of cutterstock in

them.

When

such

a

viscous

grade

is

present,

it

is

well

to

confirm

the

identification of the sample by a prolonged

smear test. Generally, the MCs and SCs will

penetrate through the paper while the RCs

will

not.

You

can

determine

this

by

observing the back side of the paper.

In a prolonged smear test, a thin

smear is made on nonabsorbent paper and

allowed to cure completely. If the viscous

cutback

is

all

RC-3000,

it

will

cure

completely in about 3 hours. When the spot

has cured completely (the cutterstock has

almost

all

evaporated),

the

smear

will

be almost pure asphalt cement (AC) and

will be hard and no longer sticky. If

the viscous sample were an MC or SC-

800 or 3,000, the spot would still be

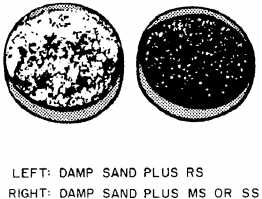

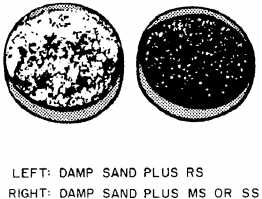

Figure 8-25.—Stone-coating test for emulsions.

uncured and, therefore, very sticky, even

after 24 hours, while the RC smear will

have become a hard, glazed spot.

Heat-Odor Test

A

heat-odor

test

is

used

to

distinguish

between

medium-curing

and

slow-curing asphalt cutback by identifying

the cutter stock as kerosene, fuel oil, or

diesel oil. A sample of the material is

heated in a closed container to retain the

vapors. (CARE MUST BE TAKEN TO AVOID THE

USE OF TOO MUCH HEAT). Medium-curing

asphalt cutback will have a strong odor of

kerosene. Slow-curing asphalt cutback will

lack the kerosene odor, but a faint odor

of motor oil may be present.

Field Penetration Test

The

field

penetration

test

is

performed

to

determine

the

approximate

hardness of the asphalt, not to pinpoint

the exact penetration number for it. To

determine if the number falls in the hard,

medium, or soft group is sufficient.

To perform this test, attempt to

push a sharpened pencil or nail into the

container

of

asphalt

(at

about

77°F),

using

a

firm

strong

pressure

of

approximately 10 pounds. If only a slight

penetration

is

made

with

considerable

difficulty,

a

hard

asphalt

cement

is

present.

When

the

penetration

is

made

slowly

but

without

great

difficulty,

a

medium asphalt cement is present. If the

penetration is made with ease, the asphalt

cement is a high penetration scale (a soft

AC).

Stone-Coating Test

When a material has been tested and

found to be an emulsion, the stone-coating

test is performed (fig. 8-25). This test is

conducted to determine if the emulsion is a

8-26