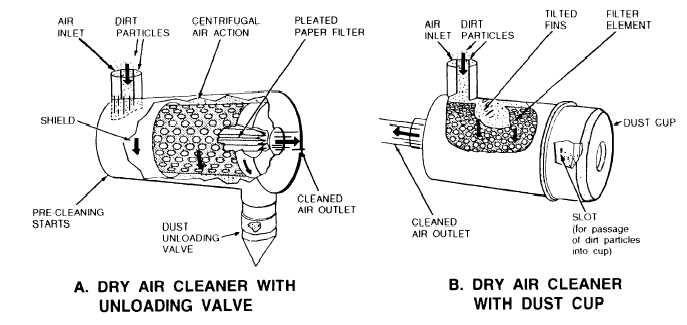

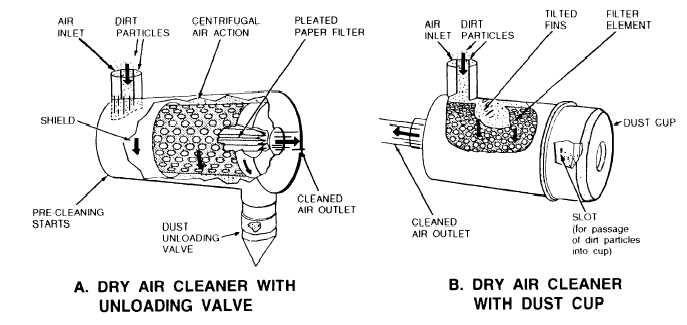

Figure 1-36.-Dry-element air cleaner.

demand for air is small. The dry air cleaner cleans the

air by passing it through layers of cloth or felt that

removes large dirt particles from the air very effectively.

Dry-Element Air Cleaners

The two most common dry-element air cleaners

used are the cleaner with an unloading valve and a

cleaner with a dust cup (fig. 1-36).

Dry air cleaners are built for two-stage cleaning:

pre-cleaning and filtering. The cleaner with the dust

unloading valve, as shown in figure 1-36, view A,

directs the air into the pre-cleaner so that it strikes one

side of the metal shield. This starts the centrifugal

suction that continues until it reaches the far end of the

cleaner housing. At this point, the dirt is collected into

the dust unloader valve located at the bottom of the

housing.

The dust unloader valve is a rubber duck-bill device

that is held closed by engine suction while the engine is

running. When the engine is shut down, the weight of

the accumulated dirt helps open the flaps so the dirt can

drop out. The cleaner with the dust air cup, as shown in

figure 1-36, view B, pulls in the air past tilted fins that

starts the centrifugal suction. When the air reaches the

end of the cleaner housing, the dirt passes through a slot

in the top of the cleaner and enters the dust cup.

Both types of pre-cleaners remove over 80 percent

of the dirt particles, greatly reducing the load on the

filters. After the air goes through the pre-cleaning stage,

it then passes through the holes in the metal jacket

surrounding the pleated-paper filter. Filtering is

performed as the air passes through the paper filter that

filters out almost all of the remaining small particles.

Checking and cleaning air cleaners equipped with

either a dust unloading valve or dust cup is part of the

daily prestart and post-operational checks and

maintenance performed by the operator. The dust

unloading valve should be inspected for cracks,

clogging, and deterioration. The dust cup should be

removed and wiped clean with a rag. Dusty filter

elements should be removed and cleaned by tapping and

rotating the filter on the heel of your hand to remove the

dust.

NOTE: Do not tap the filter on a hard surface; this

can damage the element.

When the tapping does not remove the dust, use a

compressed air cleaning gun to clean the filter

(fig. 1-37). Direct the clean dry air up and down the

pleats, blowing from inside to outside.

NOTE: To prevent rupturing the filter, you must not

allow the compressed air pressure to exceed 30 psi.

To clean with water, you first blow out the dirt with

compressed air, then flush the remainder of the dirt from

inside to outside with water. After flushing is completed,

allow the filter to dry.

1-26