electrical system, is provided with a fuse that has an

ampere rating for the maximum current required to

operate the unit.

The fuse element is made from a metal that has a

low-melting point and is the weakest point in the

electrical circuit. In case of a short circuit or other

trouble, the fuse burns out first and this opens the circuit

just as a switch would do. Visual examination of a

burned-out fuse usually provides a quick indication of

the problem. A discolored sight glass indicates the

circuit has a short either in the wiring or one of its

components. If the glass is clear, the problem may be

an overload in the circuit.

When replacing a fuse, you should ensure that it has

a rating equal to the one burned out. Also, ensure that

the malfunction that caused the failure has been

determined and repaired.

GAUGES

Just because everything checks out okay during the

prestart operation does not mean it will stay that way

throughout the workday. You must continually monitor

certain conditions, such as water temperature, oil

pressure, and so forth, to ensure the equipment is

running correctly. You monitor them by watching the

indicator (warning lights or gauges) on your equipment.

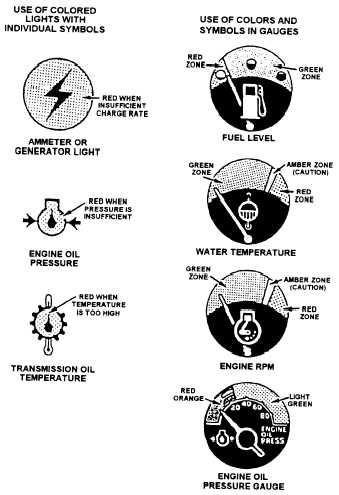

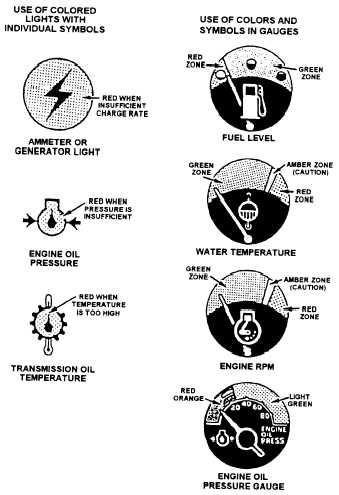

On equipment, you may see an analog type of gauge (fig.

4-7) or color-coded indicators, as shown in figure 4-8.

Figure 4-7.—Analog gauges.

Figure 4-8.-Color-coded gauges.

Water Temperature Gauge

When operating a piece of equipment, you must

monitor the water or coolant temperature gauge. If your

machine has an analog type of gauge (fig. 4-7), you must

know the correct operating temperature. Refer to the

operator’s manual to determine the operating

temperature. Anytime the temperature reading on the

gauge starts to rise, stop and determine the reason. Do

not wait until the gauge is in the red zone to investigate.

WARNING

Use extreme caution when removing a hot

radiator cap. Steam coming from the radiator

will cause severe burns.

4 - 6