towing tongue). Ensure all electrical hookups fit and are

the right length.

l When parking, ensure the parking brake is

applied and wheels are chocked.

. Safety chains must be of proper size and length

and secured properly (fig. 14- 11).

PNEUMATIC TOOLS

Pneumatic tools can be used with any type or size

compressor as long as the psi and cfm requirements for

the tool are met. In the NCF, pneumatic tools are

normally stored and checked out from the central

toolroom along with the air supply hose.

When checking out a tool, you should determine if

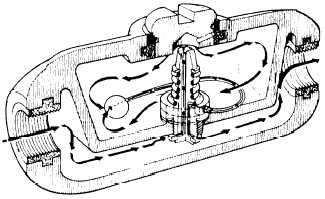

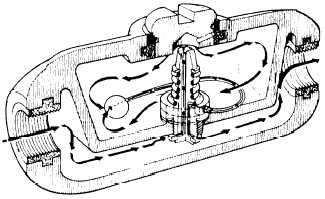

the tool needs an in-line oiler. If an in-line oiler (fig.

14- 12) is needed to provide lubrication to the tool,

follow the tool manufacturer’s recommendation for the

correct lubrication.

PAVEMENT BREAKER/

JACKHAMMER

The pavement breaker resembles a portable rotary

rock drill/jackhammer. The pavement breaker consist

Figure 14-12.—In-line oiler.

of a piston that is moving in a chamber under air pressure

and weighs between 30 to 90 pounds. The major

working parts of a pavement breaker are shown in figure

14-13. Notice no rotational mechanism is provided and

no variation in speed is possible. This is the major

difference between the pavement breaker and rotary

rock drill/jackhammer.

Pavement breaker attachments (fig. 14-14) are the

moil point, the chisel point, the asphalt cutter, and the

clay spade.

Figure 14-11.—Air compressor.

14-10