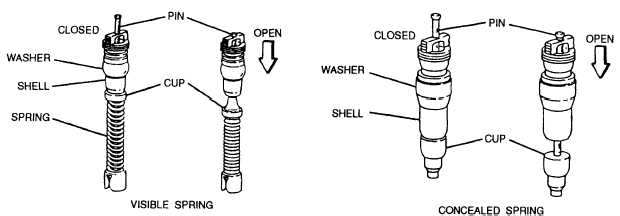

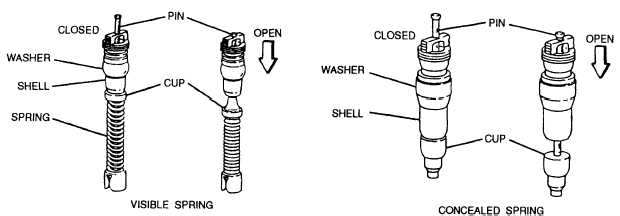

Figure 3-12.—Valve cores.

UNDERINFLATED.— An underinflated tire is

shown in figure 3-11, view B. This tire does not contain

enough air for its size and the load it must carry. It flexes

excessively in all directions and gets hot. In time, the

heat weakens the cords in the tire, and it blows out.

Underinflation also causes tread edges to scuff the road

that puts uneven wear on the tread and shortens tire life.

Never run a tire flat, or nearly flat, unless the tactical

situation in combat requires it. When run flat for even a

short distance or almost flat for a long distance, the tire

may be ruined beyond repair.

OVERINFLATED.— An overinflated tire is

shown in figure 3-11, view C. Too much air pressure

also causes tire failure. Excessive pressure prevents the

tire from flexing enough and causes it to be constantly

subjected to hard jolts. When an overinflated tire hits a

stone or rut, the cords may snap and cause a break in the

cord body. The center of the tread wears more rapidly

and does not permit equal wear across the entire tread.

Hard riding from too much air pressure also increases

wear and tear on the vehicle.

Valves

For speed and convenience during inflation, valve

stems should be readily accessible. They should be

properly centered in the valve holes and slots to prevent

scraping against the brake drums. They should be placed

so the valves extend through the wheels. Valves on the

inside duals should point away from the vehicle, and the

valves on the outside duals should point toward the

vehicle. On dual wheels, the valve of the outside dual is

placed 180 degrees from the inside valve for speed and

convenience in checking pressures and inflation. With

this arrangement, the locations of the valves are always

known even when you are checking them in the dark.

Spare tires should be mounted so that the valve is

accessible for checking and inflating.

VALVE CORES.— The valve core (fig. 3-12) is

that part of the valve that is screwed into the valve stem

and permits air, under pressure, to enter, but prevents it

from escaping. Two types of valve cores and two sizes

of each type are in use today. The two types are the

visible spring type and the concealed spring type. The

two types are interchangeable. Two sizes are provided

for the standard bore and the large bore valve stems. The

core shell has a rubber washer that provides an airtight

seal against the tapered seat inside the stem. Directly

below the shell is a cup that contains a rubber seat,

which, in the closed position, is forced against the

bottom of the shell, forming an airtight seal. The pin on

top of the valve core, when pushed down, forces the cup

away from the shell, permitting air to flow.

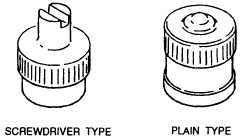

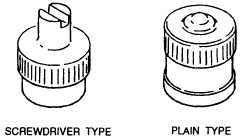

VALVE CAPS.— The valve cap (fig. 3-13) is also

a component part of the valve and is screwed onto the

end of the stem, providing a second airtight seal. The

cap also protects the threads on the end of the stem and

Figure 3-13.—Valve caps.

3 -8