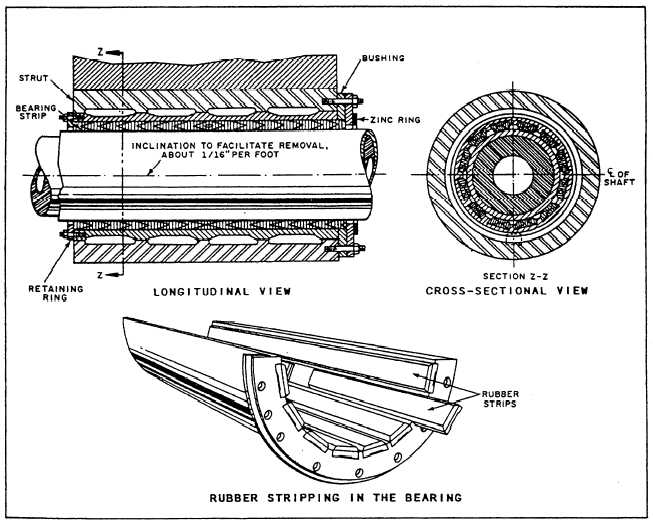

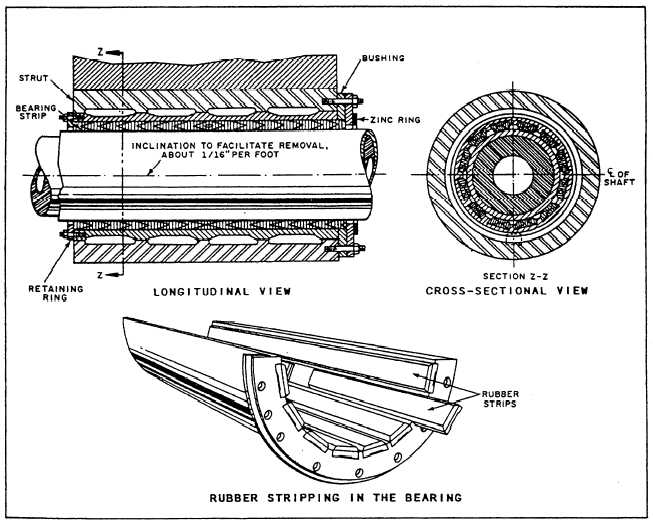

Figure 3—8.—Details of a typical underwater strut bearing.

system operations.

This proficiency combined with

local manual operating mode. The maximum rate of

leadership skills will assist you daily in your supervisory

role.

CRP/CPP SYSTEMS OPERATIONS

In this section, we will briefly cover routine and

emergency operations of the CRP/CPP systems. Since

the various ship systems are functionally the same, we

will not indicate ship type except when necessary.

However, if you need to review the basic design and

operational characteristics of these systems, consult

GSE3/GSM3, volumes 1 and 2.

Routine Operation

Propeller pitch changes can be made through the full

range of travel in one continuous movement. The pitch

change can be made in automatic, remote manual, or

pitch change, 30 seconds from full ahead to full astern,

is determined by the response of the hydraulic system.

Pitch change rate is NOT determined by the speed of

movement of the control lever.

The CRP/CPP systems were designed to maximize

the ability of the ship’s propulsion GTE to accelerate

and decelerate rapidly and to enhance maneuverability.

To further enhance the systems’ performance and to

make them more “user friendly,” some subtle changes

were made. These changes have been installed on the

newest gas turbine ship platform, the DDG-51 class

ship. The following sections will explain some of these

changes and the contributions they make to system

performance.

As a GS supervisor, you should be aware of the

changes incorporated in the CRP/CPP systems installed

on the DDG-51 class ships and the advantages they offer

3-12