stem-stuffing, stem-gland, and gland-stuffing box

clearances.

If GFY is not available, you can install a ring of

conventional packing as anti-extrusion rings.

However, the use must be temporary. At the earliest

opportunity, disassemble, inspect, and repack the valve

using GFY anti-extrusion rings with CRP.

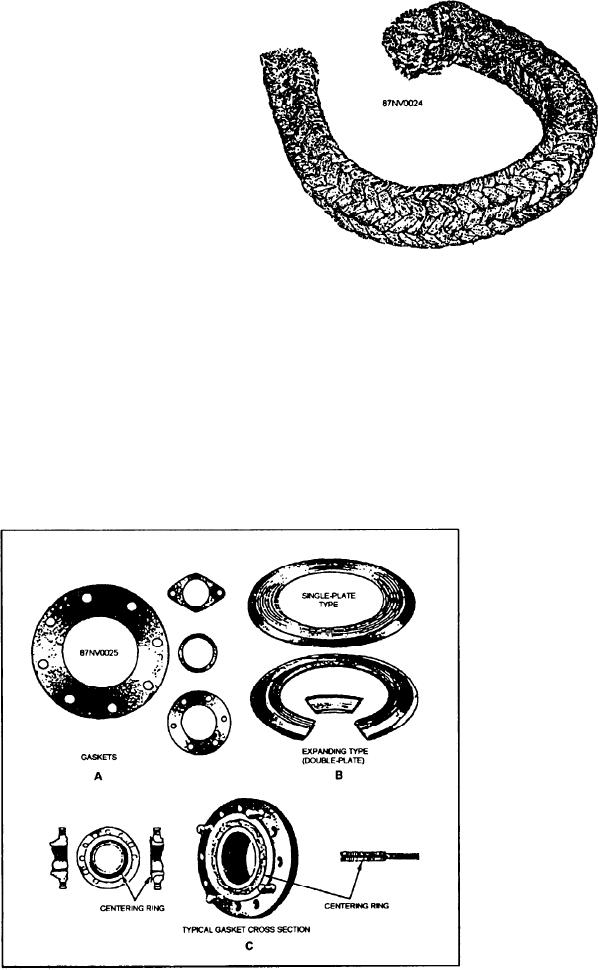

GFY packing, figure 15-25, is a severe service

packing ideal for use in difficult fluid-handling

applications. It is unaffected by the most destructive

corrosive fluid substances. It will withstand extreme

temperatures of over 1000F encountered in valve

stuffing boxes. GFY packing is self-lubricating. It has

exceptional heat dissipation characteristics. This

allows tight packing adjustment to make leakage almost

Figure 15-25.--Graphite filament yarn.

nonexistent. It also provides maximum protection

against stem scoring. This packing greatly reduces

passes through the stuffing box. Inspect the interior of

system fluid loss, maintenance, and downtime to

the stuffing box itself. Take whatever steps you can to

provide longer, trouble-free valve life. GFY is

ensure that the packing will make contact with the

available in sizes from l/8 inch to 1 inch square on

straightest, smoothest possible surface. (You may have

spools.

to have the shaft repaired and refinished, or replaced.)

NOTE: Regardless of how good the packing

GASKETS

material may be, if the surface of the shaft passing

through the stuffing box is scored or damaged in any

At one time, fixed steam joints could be

way, the packing will not last long. When replacing

satisfactorily sealed with gaskets of compressed

packing, carefully inspect the shaft in the area where it

asbestos sheet packing (fig. 15-26, view A). However,

Figure 15-26.--Fixed joint gaskets. A. Sheet gaskets. B. Serrated-face metal gasket. C. Spiral-wound metallic gasket.

15-23