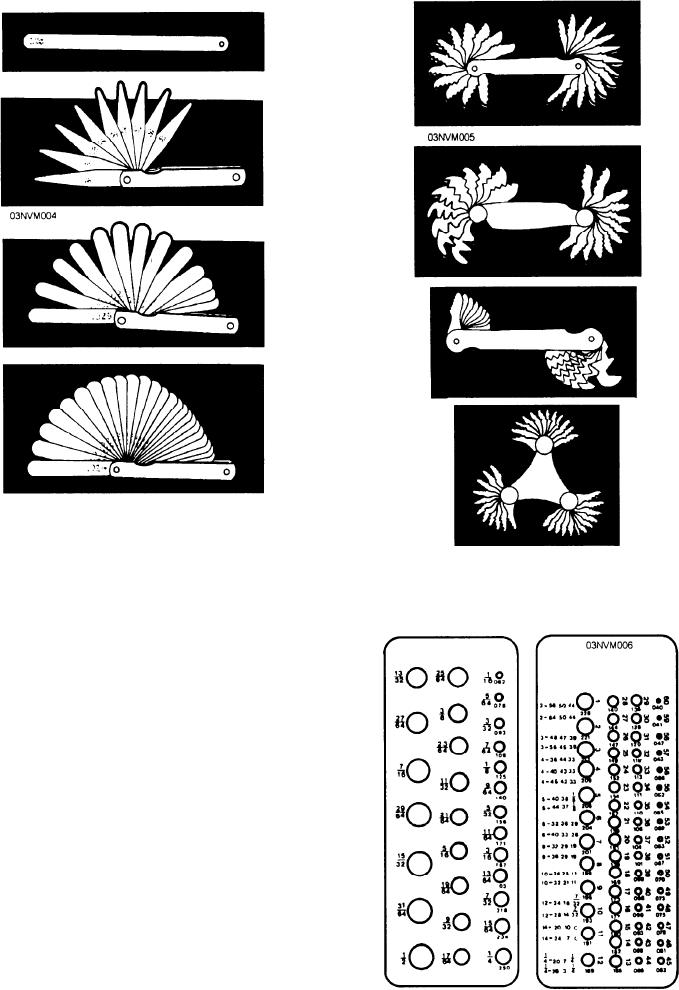

Figure 5-4.--Thickness (feeler) gauges.

Figure 5-5.--Screw-pitch gauges.

more blades may be combined to take readings of

various thicknesses.

Screw-Pitch Gauges

Screw-pitch gauges (fig. 5-5) are made for checking

the pitch of U.S. Standard, Metric, National Form, and

V-form cut threads. You will use them to determine the

correct thread pitch of an unknown thread on a bolt,

inside a nut, or in choosing the correct tap or die for

threading stock or tapping a hole. Each thread gauge is

marked in number of threads per inch. To take a meas-

urement, simply lay the gauge on the thread. The correct

gauge will fit the thread of the bolt perfectly with no

light showing between the gauge and the threads of the

bolt. The pitch of the screw thread is the distance

between the center of one tooth to the center of the next

tooth.

Drill Gauges

The twist drill and drill rod gauge has a series

of holes with size and decimal equivalents stamped

adjacent to each hole, as shown in figure 5-6. Drill

gauges use either a letter, number, decimal, or fraction

Figure 5-6.--Drill gauges.

5-5