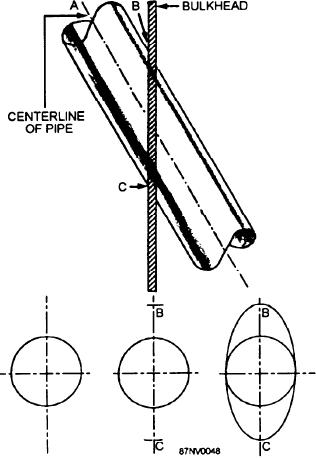

across the long axis of the ellipse above and below the

center point. Sketch in the remainder of the ellipse. You

now have a useable layout for a pipe to pass through a

deck or bulkhead at an angle.

MAKING TEMPLATES AND TARGETS

Frequently, the section of pipe to be replaced will

have a bend in it. The replacement section will have to

be exactly like the portion that is removed. You can get

an exact fit by using templates and targets.

Templates are made from wood, wire, or small

tubing. You will find them valuable in preparing new

installations, as well as in repair work When properly

made and correctly used, they provide an exact guide

for bends and flange positions. The method of making

and using a template is illustrated in figure 16-10.

A wood template is formed by securing blank

wooden disks to the flanges of the fixed-position pipes.

This is shown in view A of figure 16-10. Insert gaskets

of the proper thickness between the wooden disks and

the fixed flanges. This will provide the proper clearance

for the permanent gasket installation. Next cut a 2 by 4

to fit snugly between the flanges. Secure the 2 by 4 by

nailing triangular wood braces to the wood flanges and

to the 2 by 4. The template can now be taken to the shop.

Figure 16-9.--Finding the length of an elliptical hole.

A target (or reverse template, as it is sometimes called)

can now be made. (See fig. 16-10, view B.)

Targets can be made of wood, but metal is the

or bulkhead. The method used is shown in figure 16-9

preferred material (fig. 16-10, view C) due to its

and described in the following paragraphs.

durability, strength, and flame resistance. The targets

Draw a line to represent the deck or bulkhead that

are constructed of ordinary or blank flanges welded to

the pipe will pass through. Use a protractor to lay out

angle iron or pipe. The target is then welded a minimum

and draw a line at the angle that the pipe will pass

of 12 inches off of a target deck (a large metal slab) to

through the deck or bulkhead. Draw this line as the

make it easier to work on the new section of pipe. The

centerline (A) to represent the center of the pipe. Then

target is then braced to prevent movement while

working with the target. Remember, the target is your

draw a parallel line on each side of the centerline. The

permanent pattern by which you are working off of and

distance between the parallel lines and the centerline is

any movement, however so slight, will cause mis-

equal to one-half the outside diameter of the pipe or

alignment in your finished product. Only after the

tube. This measurement must be made perpendicular

piping assembly has been manufactured, tested, and

from the pipe centerline. Measure the distance from B

installed may you remove the target from the target

to C on the bulkhead line. This distance is the long axis

deck. The target deck can then be used over again for

of the elliptical hole.

another target.

Locate the halfway point between the two points

In repair work, the target is usually made directly

marked B and C. This is the center point of the hole to

from the section being repaired. The pipe section then

be cut. Through this point, draw a horizontal line at right

serves as the template. This procedure is illustrated in

angles to the line representing the bulkhead. With a pair

view D of figure 16-10.

of dividers, scribe a circle equal to the outside diameter

of the pipe. Then set the dividers at a radius equal to

A centerline template is made to conform to the

one-half the distance from B to C. Now scribe an arc

bend, or bends, of the pipe to be made. It is used to lay

16-10