in the opposite direction. Since the two bevel

gears (G and H) are fixed on the shaft

with F, they also turn. These bevel

gears, meshing with the horizontal bevel gears (I

and J), cause I and J to swing the front ends of the

telescopes to the right. Thus with a simple system of

gears, it is possible to keep the two telescopes

pointed at a moving target. In this and

many other applications, gears serve one

purpose: to change the direction of

motion. GEARS USED TO

CHANGE SPEED As youve already

seen in the eggbeater, you use gears to

change the speed of motion. Another example

of this use of gears is in your clock or watch. The

mainspring Slowly unwinds

and causes the hour hand to make one

revolution in 12 hours. Through a series-or

train-of gears, the minute hand makes one

revolution each hour, while the second

hand goes around once per minute.

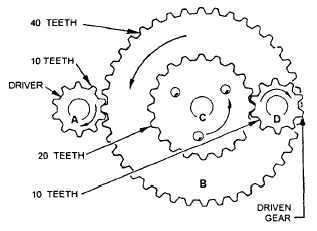

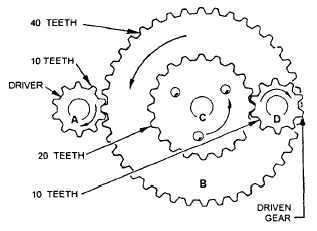

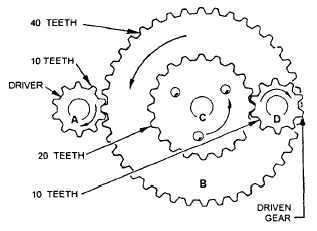

Figure 6-9 will help you to understand how

speed changes are possible. Wheel A

has 10 teeth that mesh with the 40

teeth on wheel B. Wheel A will have to rotate

four times to cause B to make one revolution. Wheel C

is rigidly fixed on the same shaft with B. Thus, C

makes the same number of revolutions as

B. However, C has 20 teeth and meshes

with wheel D, which has only 10 teeth.

Hence, wheel D turns twice as fast as wheel C.

Now, if you turn A at a speed of four revolutions per

second, B will rotate at one revolution per

second. Wheel C also moves at one

revolution per second and causes D

to turn at two revolutions per second. You get

out two revolutions per second after having put in

four revolutions per second.

Thus, the overall speed

reduction is 2/4or 1/2that means you got half the

speed out of the last driven wheel you put into the

first driver wheel.

You can solve any gear speed-reduction problem

with this formula:

Figure 6-9.-Gears can change speed of applied motion.

Now use the formula on the gear train of figure 6-9.

To obtain any increase or decrease in speed you,

must choose the correct gears for the job. For

example, the turbines on a ship have to

turn at high speeds-say 5,800 rpmif

they are going to be efficient. The

propellers, or screws, must turn rather slowlysay

195 rpmto push the ship ahead with maximum

efficiency. So, you place a set of reduction

gears between the turbines and the

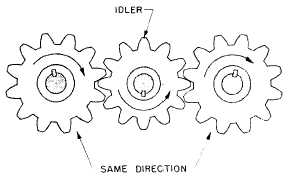

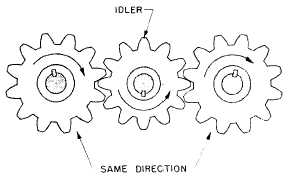

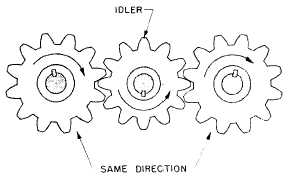

propeller shaft. When two external

gears mesh, they rotate in

opposite directions. Often youll want to avoid this. Put

a third gear, called an idler, between the driver and

the driven gear. Dont let this extra

gear confuse you on speeds. Just

neglect the idler entirely. It doesnt change

the gear ratio at all, and the formula still applies. The idler

merely makes the driver and its driven gear turn in

the same direction. Figure 6-10 shows

you how this works. where

=

=

=

=

speed of first shaft in train

speed of last shaft in train

product of teeth on all drivers

product of teeth on all driven gears

Figure 6-10.-An idler gear.

6-5