ENGINEMAN 1 & C

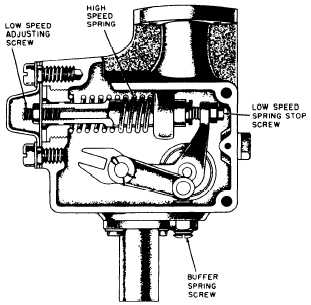

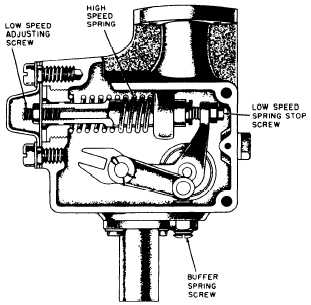

(low speed) spring. Maximum speed control is ef-

fected by the action of the high speed (small)

flyweights acting against a heavy (high speed)

spring. (See figure 3-16.)

Mechanical governor faults usually manifest

themselves in speed variations; however, not all

speed variations indicate governor faults. When

improper speed variations appear do the

following:

1. Check the load to be sure that speed

changes are not the result of load fluctuations.

2. If the load is found to be steady, check the

engine to be sure all cylinders are firing properly.

3. Make sure there is no binding in the gover-

nor mechanism or operating linkage between

governor and engine, and that no binding exists

in the injector control rack shaft or its mounting

brackets. If you find no binding anywhere and

the governor still fails to control the engine prop-

erly, you may assume the governor is worn or

unfit for further service until the unit has been

completely disassembled, inspected, and rebuilt

or replaced.

121.23

Figure 3-16.—Mechanical governor control mechanism.

Adjustment procedures for the replacement of

any governor are listed in the manufacturer’s

instruction manual and should be followed with

particular attention given to the precautions listed.

OVERSPEED SAFETY DEVICES

Mechanical overspeed trips depend on the cen-

trifugal forces developed by the engine and should

be maintained in good working condition. A

faulty overspeed device can endanger not only the

engine but also personnel if the engine explodes

or flies apart because of uncontrolled speed.

The engine instruction manual contains infor-

mation as to the speed at which the overspeed is

supposed to function. Most overspeed trips are

adjustable. Prior to making any change in the ad-

justment of the overspeed trip, determine if the

engine did not trip out for some reason other than

the action of the element of the overspeed trip.

It is highly advisable that you first check the ac-

curacy of the tachometer and then test the

overspeed trip. All spring tension adjustments and

linkage adjustments to an overspeed trip are

critical. Instructions given for making these ad-

justments are found in the manufacturer’s instruc-

tions manual and must be followed.

Hydraulic overspeed trips are extremely sen-

sitive to dirt. Dirt or lacquer-like deposits may

cause a trip to bind internally. The speed sensitive

element must be kept clean and so should all parts

of the linkage and mechanisms incorporated in

this speed sensitive element. When painting

around the engine, the painter should be cau-

tioned against allowing paint to fall on joints,

springs, pins, and other critical points in the

linkage.

All linkage binding should be eliminated. If

parts are bent, badly worn, improperly installed,

dirty, or if their motion is restricted by some other

part of the engine, the trip will not function

properly. On occasion the drive shaft of the

overspeed trip may be broken and prevent rota-

tion of the flyweight and the overspeed trip.

Insufficient oil in the hydraulic trip may be

another source of this problem. Oil should be

maintained at the level specified in the instruc-

tion manual.

The cause of any malfunction should be deter-

mined and eliminated. This will involve cleaning

the trip and its linkage, removing the source of

3-24