however, the permissible amount in each bin is usually

specified.

Daily visual inspection of the screens for cleanliness

is recommended, preferably before the start of

operation. When conditions warrant, the screens should

be cleaned.

NOTE: Always make sure the bolts securing the

screens are tight.

Hot Bins

Hot bins are used to store the heated and screened

aggregates temporarily in the various sizes required.

Each bin is an individual compartment or a segment of

a large compartment divided by partitions. A properly

sized hot-bin installation should be large enough to

prevent running out of material when the mixer is

operating at full capacity. Bin partitions should be tight,

free from holes, and of sufficient height to prevent

intermingling of the different size aggregates.

Hot bins usually have indicators that tell when the

aggregates fall below a certain level. These indicators

may be either electronic or mechanical. Each hot bin

should be equipped with an overflow pipe to prevent

excess amounts of aggregate from backing up into the

other bins. The overfill pipes should be set up to stop

overfilling of the bins. When a bin overfills, the screen

above the bin rides on the aggregate, resulting in heavy

carry-over and possible damage to the screen. Overflow

vents should be checked frequently to ensure they are

free flowing.

Sometimes, very fine aggregate particles build up

in the bin corners. When this buildup of aggregate

collapses, it can result in an excessive amount of fines

in the mix. This rush of fine materials normally occurs

when the aggregate in the bin is drawn down too low.

This condition can be controlled by having fillet plates

welded in the bin corners to eliminate the 90-degree

angles and by maintaining the proper aggregate level in

the bin.

Other potential obstacles to obtaining a good mix

includes a shortage of aggregate in one bin or excess in

another bin, worn gates (at the bottom of the bins) allow

leakage of aggregate, and sweating of the bin walls.

These obstacles must be overcome. Bin shortages or

excesses can be corrected by adjusting the cold feed.

Sweating occurs when moisture vapor in the aggregate

and in the air condenses on the bin walls. his usually

happens only at the beginning of the day’s operation or

when the coarse aggregate is not thoroughly dried.

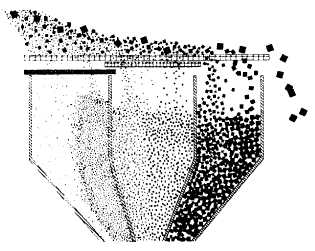

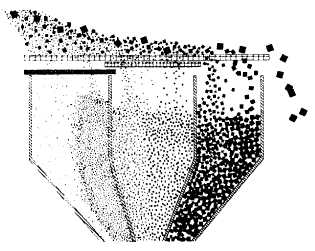

Figure 8-11.-Segration of material in the bot bins.

Sweating may accumulate dust that, when released

suddenly, will add unwanted fines in the mix.

Hot-Bin Sampling

Most modern hot-mix asphalt plants are equipped

with devices for sampling hot aggregate from the bins.

These devices vary in design but usually serve to divert

the flow of aggregate from the feeders, or gates, under

the bins into sample containers. On continuous-flow

plants, the best place to obtain a sample is from the

feeder gates as the material is deposited onto the elevator

leading to the pugmill. Sampling facilities must be

constructed and located so that the samples obtained will

be representative of the material in the bins.

From the flow of aggregate over the screens, the

finer aggregates fall to the near side of the bins and

coarser aggregates fall to the far side (fig. 8-11). When

the aggregate is drawn from a bin by opening a gate at

the bottom, the flow of aggregate consists

predominantly of fine aggregate at one edge and coarse

aggregate at the other; therefore, the position of the

sampling device in the flow of aggregate determines

whether the sample will be composed of the fine portion,

the coarse portion, or will be an accurate representation

of all the aggregate in the bin. This condition is critical

in the bin that contains the fine aggregate since the

asphalt required in the mix is influenced heavily by the

aggregate from this bin.

Stratification (vertical layering) of sizes in the fine

bin may be caused by variation of grading in the

stockpiles or by erratic feeding of the cold aggregate.

When this form of segregation exists, representative

8-9