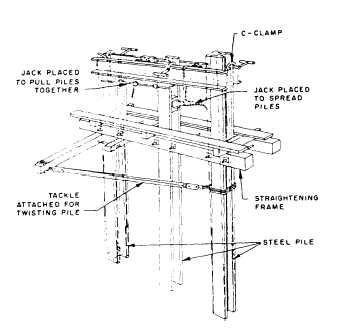

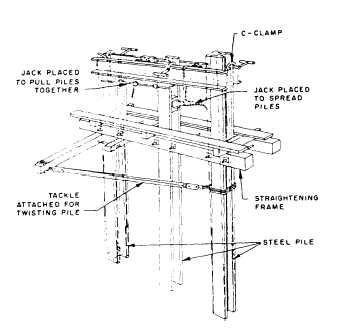

Figure 12-73.—Aligning and capping steel pile bents.

driving, or that is to be salvaged (steel sheet piles are

frequently salvaged for reuse) is usually extracted

(pulled). Pulling should be done as soon as possible

after driving; the longer the pile stays in the soil, the

more compact the soil becomes, and the greater the

resistance to pulling will be. Methods of pulling piles

are as follows:

1. In a direct lift method, a crane palls the pile.

The crane hoist line is rigged to the pile through the use

of wire rope rigging, and an increase in pull is gradually

applied to the pile. Lateral blows from a skull cracker

(heavy steel ball swung on a crane line to demolish

walls) or a few light blows on the butt or head with the

pile-driving hammer are given to break the skin friction,

and the crane pull is then increased. If the pile still

refuses to extract, it may be loosened by jetting, air

extractors, or beam pullers.

2. The 5,000-pound pneumatic, or steam, hammer

may be used in an inverted position to pull piles. The

hammer is turned over and the wire rope rigging is

attached to it and the pile is extracted. A pneumatic

extractor may also be used. The crane line, holding the

hammer or extractor, is hoisted taut; and the upward

blows of the hammer ram on the sling, plus the pull of

the crane hoist, are usually enough to pull the pile.

3. Tidal lift is often used to pull piles driven in

tidewater. Rigging, wrapped around the piles, is

attached to barges or pontoons at low tide; the rising tide

pulls the piles as it lifts the barges or pontoons.

Types of Piles

The principal use of piles is for the support of

bridges, buildings, wharves, docks and other structures,

and in temporary construction. A pile transfers the load

into an underlying bearing stratum by either of the

following:

1. Friction along the embedded length of the pile

2. Point bearing plus any bearing from the taper of

the pile

A pile maybe classified roughly as friction or end

bearing, according to the manner in which they develop

support. The load must be carried ultimately by the soil

layers around and below the points of the piles, and

accurate knowledge of the compressibility of these soil

layers is of utmost importance.

Some of the common terms used with piles are as

follows:

1. Piles. A pile is a load-bearing member made of

timber, steel, concrete, or a combination of these

materials, usually forced into the ground to transfer the

load to underlying soil or rock layers when the surface

soils at a proposed site are too weak or compressible to

provide enough support.

2. Pile foundation. A pile foundation is a group of

piles that supports a superstructure or a number of piles

distributed over a large area to support a mat foundation.

3. Bearing piles. Piles that are driven vertically

and used for the direct support of vertical loads are

called bearing piles.

Bearing piles transfer the load

through a soft soil to an underlying firm stratum. They

also distribute the load through relatively soft soils that

are not capable of supporting concentrated loads.

4. End-bearing piles. Typical end-bearing piles are

driven through very soft soil, such as a loose silt-bearing

stratum underlain by compressible strata. Remember

this factor when determining the load the piles can

support safely.

5. Friction piles. When a pile is driven into soil of

fairly uniform consistency and the tip is not seated in a

hard layer, the load-carrying capacity of the pile is

developed by skin friction. The load is transferred to the

adjoining soil by friction between the pile and the

surrounding soil. The load is transferred downward and

laterally to the soil.

6. Combination end-bearing and friction piles.

Many piles carry loads by a combination of friction and

end bearing. For example, a pile may pass through a

12-51