125 pounds per square inch (psi), the governor stops the

compressor from pumping air. When the tank pressure

falls to the cut-in pressure at about 100 psi, the governor

allows the compressor to start pumping again.

Air Storage Tanks

Air storage tanks (reservoirs) are used to hold

compressed air. The number and size of air tanks varies

among vehicles. The tanks hold enough air to allow the

brakes to be used several times, even if the compressor

stops working.

NOTE: Compressed air usually has some water and

some compressor oil in it which is bad for the air brake

system. For example, the water can freeze in cold

weather and cause brake failure. The water and oil tend

to collect in the bottom of the air tank; therefore, each

air tank is equipped with a drain valve in the bottom.

The two types of drain valves areas follows:

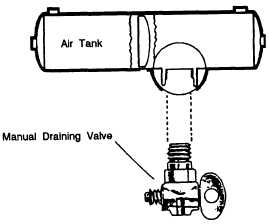

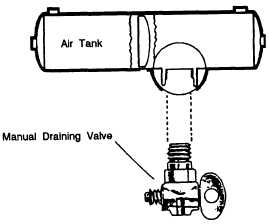

1. The manual valve shown in figure 3-45 is

operated by turning it a quarter turn or by pulling a cable.

Part of your post-operational procedures is to drain all

air tanks at the end of each day.

2. The automatic valve automatically expels the

water and oil. This system may also be equipped with a

manual drain.

Alcohol Evaporator

Some air brake systems have an alcohol evaporator

to put alcohol into the air system. This helps reduce the

risk of ice in air brake valves and other parts during cold

weather. Ice inside a brake system can make the brakes

stop working.

Figure 3-45.-Air tank manual drain valve.

If your vehicle has an alcohol system, the container

should be checked during each prestart operation and

filled up as necessary. Daily draining of the air tanks is

still required to get rid of the water and oil.

Safety Valve

A safety relief valve is installed in the first tank into

which the air compressor pumps air. The safety valve

protects the tank and the rest of the system from too

much pressure. The valve is usually set to open at 150

psi. If the safety valve has to release air pressure,

something is wrong in the air brake system. This should

be documented to inform the mechanic inspectors.

Brake Pedal

The brakes are applied by depressing the brake

pedal (also called the foot valve, or treadle valve)

that gives the operator control of the air brake

system. When the brake pedal is engaged, air from

the air tanks flows through the brake pedal valve

through the brake lines to the brake chambers close to

the wheel brakes that contain flexible diaphragms. The

force of the air admitted into these chambers causes the

diaphragms to operate the brake shoes through a

mechanical linkage.

Pushing the pedal down harder applies more air

pressure. Letting up on the brake pedal reduces the air

pressure and releases the brakes. Releasing the brakes

allows some compressed air out of the system; therefore,

the air pressure in the tanks is reduced and it must be

recharged by the air compressor. Pressing and releasing

the pedal unnecessarily may release air out faster than

the compressor can replace it, and should the pressure

become too low, the brakes cannot work properly and

brake failure will occur.

Pressure Gauge

An air pressure gauge lets you know if you have

proper air pressure within the reservoir. A low air

warning device should cut on before the pressure

drops to less than 60 psi in the air tank. This gauge is

usually on the instrument panel of a truck or bus. If the

pressure fails to buildup or exceeds the maximum limits

after building up, secure the truck until the fault is

corrected.

Hand Brake Valve

Independent control of brakes is necessary under

bad conditions, especially if you have to put on the

3-25