the NCF, are governed by a pressure control system,

adjusted to compress air to a maximum pressure of

100 pounds per square inch (psi). Compressor units are

available in reciprocating, rotary, or screw design.

Compressors are classified as either single-stage or

multistage. A single-stage compressor has one

compressing element that compresses the air from the

initial intake pressure to the final discharge pressure in one

step. The multistage compressor has more than one

compressing element. The first stage compresses the air

to an intermediate pressure, then through one or more

additional stages to final discharge pressure. The

multistage system is more efficient than the single-stage

system, because the air cooling that occurs between stages

reduces buildup of pressure due to a temperature rise.

All military construction compressors are governed

by a pressure control system. In a reciprocating

compressor, this control system causes the engine to

idle and the suction valve to remain open when the

pressure reaches a set maximum. When the air pressure

drops below a set minimum, the pressure control system

causes the engine to increase speed and the suction valve

to close, starting the compression cycle again. The

rotary compressor output is governed by varying the

engine speed. The engine operates automatically at the

speed needed to compress enough air to supply the

demand at a fairly constant pressure. When the engine

has slowed to idle because of low demand, a valve

throttles the amount of free air that may enter the

compressor.

The screw compressor output is controlled

automatically and provides a smooth, uninterrupted

capacity from full load to no load in response to the

demand for air. This capacity is achieved by a floating

speed engine control and a variable inlet compressor.

COMPRESSOR CAPACITY

The capacity of an air compressor is determined by

the amount of free air (at sea level) that it can compress

to a specified pressure, usually 100 psi per minute, under

the conditions of 68°F and a relative humidity of 38

percent. This capacity is expressed in cubic feet per

minute (cfm) and is usually included in the

nomenclature of the compressor.

The number of pneumatic tools that can be operated

at one time from an air compressor depends on the air

requirements of each tool; for example, a 55-pound class

rock drill requires 95 cfm of air at 80 psi. A 210-cfm

compressor can supply air to operate two of the drills,

because their combined requirements is 190 cfm.

However, if a third such drill is added to the compressor,

the combined demand is 285 cfm, and this condition

overloads the compressor and the tools and results in

serious wear.

NOTE: When the pressure and volume of air to a

pneumatic tool drops 10 percent below the designed

minimum, the tool efficiency is reduced 41 percent.

Compressor Location

Install the compressor unit so it is as close to level

as possible. Compressor design permits a 15-degree

lengthwise and a 15-degree sidewise limit on

out-of-level operation. The engine, not the compressor,

is the limiting factor. When the unit is to be operated

out of level, you should be sure to do the following:

1. Keep the engine crankcase oil level on the full

mark with the unit level.

2. Ensure the compressor oil gauge shows full with

the unit level.

Compressed Air System

A compressed air system consists of one or more

compressors, each with the necessary power source,

regulation, intake air filter, aftercooler, air receiver,

connecting piping, and a distribution system to carry the

air to points of use.

The object of installing a

compressed air system is to provide enough air at the

work area at pressures adequate for efficient operation

of pneumatic tools.

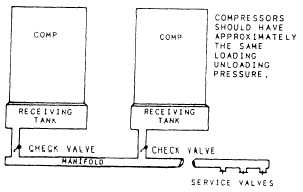

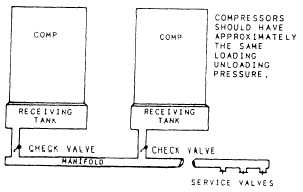

Many construction jobs require more cfm than one

compressor can produce. Also, terrain conditions often

create problems of distance from the compressor to the

operating tool. Since the air line hose causes a loss of

pressure (friction loss) at distances farther than 200 feet,

a system has been devised for efficient transmission of

compressed air over longer distances. This system is air

manifolding (fig. 14- 10).

Figure 14-10.—Methods of manifolding compressors.

14-8