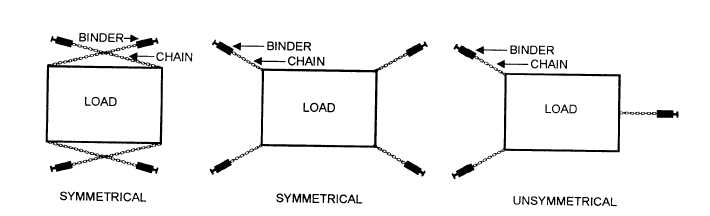

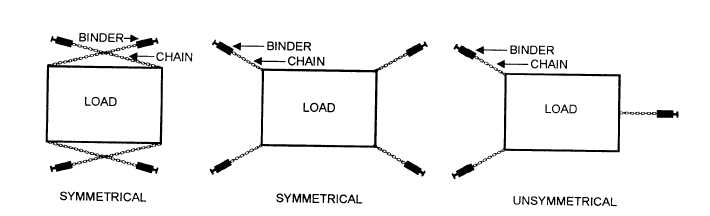

Figure 7-33.—Symmetrical tie-down pattern.

should be shaped to fit snugly against the cargo and

should be secured to the deck of the trailer to prevent

the cargo from moving. Bracing is also used to prevent

movement of the cargo. Bracing is placed from the

upper part of the cargo to the floor and/or walls of the

cargo compartment.

Because cargo loads have a tendency to shift, a

common rule of thumb is to inspect the cargo and the

securing devices before departing and within 25 miles

after beginning a trip. Always check the cargo and

securing devices as often as necessary during a trip to

keep the load secured. Inspect the cargo and securing

devices after you have driven for 3 hours or 150 miles

and after every break taken during the trip.

LOOSE MATERIAL.— Dump trucks are often

used to haul loose material. Soil, aggregate, and sand are

examples of cargo that is categorized as loose material.

When you are operating dump trucks, be sure that no

part of the load can fall off your truck when making

turns. You should stop loading before it reaches the top

of the side or end gate. Dirt spilled in curves and turns

creates driving hazards and should be cleaned up daily.

Another hazard created by loose material is a broken

windshield caused by aggregate falling from dump

trucks.

NOTE: In some states and on some deployment

locations, it is a requirement that all loose material loads

carried in dump trucks must be covered.

BUILDING MATERIAL.— When loading steel,

lumber, or anything that must be unloaded with a forklift

or crane, you should place 4 by 4 timbers or pallets

under the load. This helps get forks or cables in and out

from under the load

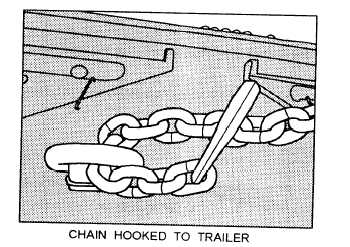

RESTRAINTS.— Loads must be secure enough to

prevent movement in any direction, which means

movement forward, aft, vertically, and horizontially.

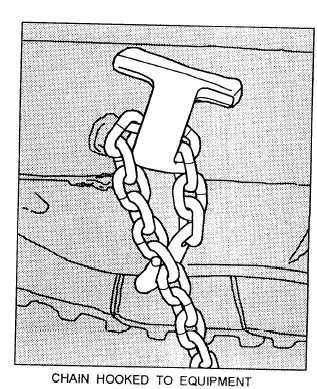

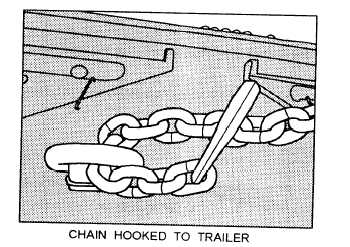

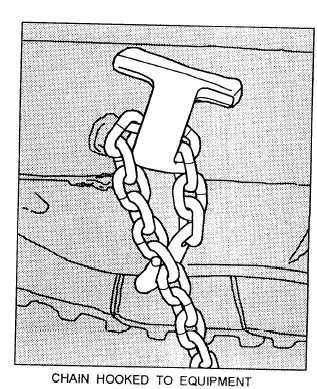

Figure 7-34.—Chains properly hooked on the equipment and

trailer tie-down eyes.

7-28