to the manufacturer’s recommendations for the

specified operating condition; that is, ideal, moderate,

or severe.

IDEAL CONDITION.— An ideal condition is

when a truck is operated over improved, level roads,

such as asphalt or concrete, at constant, relatively

moderate speeds with no adverse weather or road

conditions. Under these conditions, recommended

payload equals 100 percent of maximum permissible

payload.

MODERATE CONDITION.— A moderate con-

dition is when a truck is operated at high speeds over

improved highways, such as asphalt or concrete, with or

without long or steep grades. Moderate conditions also

include operating at moderate speeds over semi-

improved roads with gravel or equivalent surfacing, in

gently rolling country with few steep grades and no

adverse weather or road conditions. Under these

conditions, recommended payload equals 80 percent of

maximum permissible payload.

SEVERE CONDITION.— A severe condition is

when the vehicle is operated off the highway on rough

or hilly terrain or over unimproved or pioneer access

roads with deep ruts, holes, or steep grades. These

conditions also include operating where traffic has

created deep holes or ruts in heavy snow, covering

normally good city streets or highways. Under these

conditions, the recommended payload equals 64 percent

of the maximum permissible payload.

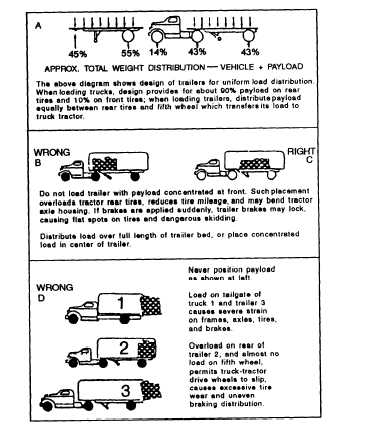

Weight Distribution

Distribution of cargo has a definite bearing on the

life of tires, axles, frame, and other parts of the vehicle.

The fact that a truck or trailer is not loaded beyond its

gross vehicle weight capacity does not mean that the

individual tires and axles may not be overloaded by

faulty distribution of the cargo. Additionally, states have

maximums for GVW, GCW, and axle weights. Axle

weights prevent the overloading of bridges and

roadways. Some examples of proper and improper

placement of the load are shown in figure 7-28.

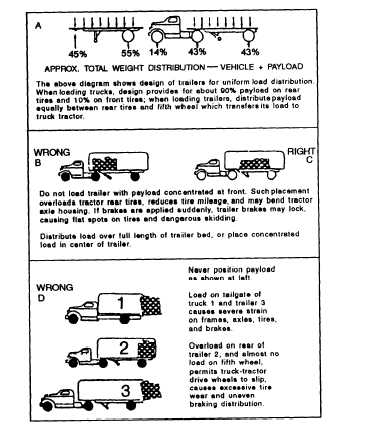

To load a truck or tractor-trailer properly, you have

to determine the center of the payload. In a truck, the

position of the center of the payload is the center of the

body or the point midway between the rear of the

driver’s cab and the tailgate. In a tractor-trailer unit, the

position of the center of the payload is roughly the center

of the trailer body, because the front wheels of the tractor

seldom carry any of the payload. When you are loading,

ensure that the maximum capacity of the vehicle is not

7-25

Figure 7-29.—Distribution of weight.

exceeded over any one axle and, if possible, that loads

are distributed so there is less-than-maximum axle

loading. Examples of approximate distribution of total

weight are shown in figure 7-29.

The payload weight must be distributed over the

body properly so the percentage of weight carried by the

front axle and that carried by the rear axle equals the

ratio for which the vehicle was designed, as shown in

figure 7-29.

Loading Cargo

The tractor-trailer can be adapted to transport

various types of materials, such as fragile, bulky,

compact, dense, rough and high center-of-gravity items.

To accommodate a variety of items, you must plan the

load, properly prepare the tractor-trailer, and secure the

load to the vehicle. Securing the load by restraining it

with proper lines, cargo straps, chains, or fastened by

tie-downs or binders should keep it from shifting or

falling off the vehicle. Should a load fall from a vehicle,

it could foul underpasses, culverts, bridge abutments,

and create a hazard to pedestrians. Protect fragile items