change when rotating a load from one quadrant to

another. This information is provided on the crane load

chart.

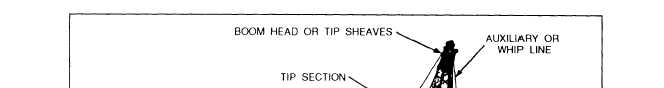

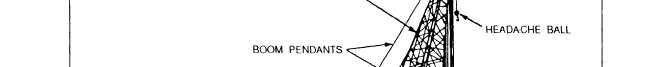

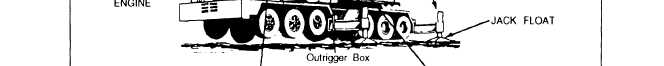

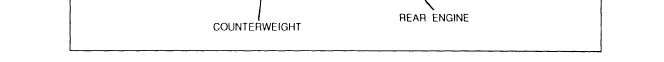

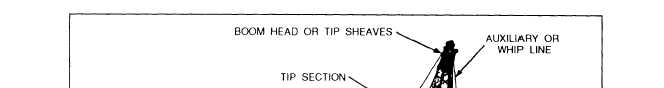

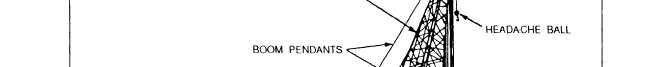

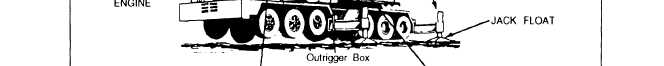

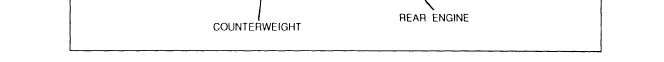

LATTICE BOOM CRANE

The major components of a lattice boom crane are

shown in figure 12-11.

Inspecting each of these

components is part of the operator’s prestart inspection.

The lattice boom supports the working load and is

the most common boom used in the NCF. It is used on

all types and makes of cranes and is mounted at the boom

butt on the revolving superstructure. The basic boom

consists of the boom butt and boom tip, and the length

is increased by adding boom extensions.

Boom Sections

Lattice boom sections are made of lightweight, thin

wall, high strength alloy tubular or angle steel and are

designed to take compression loads. The most common

boom is tubular. Terminology of a lattice boom section

is shown in figure 12-12.

Manufacturers have set a zero tolerance on rust,

bent lacings or cords, cracked welds, and other problems

that affect the strength of the lattice boom. This zero

tolerance requires crane crews to use extreme care when

handling unused sections with forklifts, storing unused

sections away from traffic areas, transporting and

securing sections on tractor-trailers, and preventing

equipment or obstacles from running into the boom

while mounted on the crane during transport,

performing operations, or when parked.

As outlined in the Management of Weight-Handling

Equipment, Maintenance and Certification, NAVFAC

P-307, all lattice boom cranes with structural damage to

the main cords of the boom must be immediately

Figure 12-11.—Lattice boom crane components.

12-6