Figure 9-19.-Step-loading method.

Loader Operation

A front-end loader can dig excavations, such as

building foundations and other belowground areas, if

the material to be excavated is not too hard.

Belowground operations require construction of a ramp

into the excavation to bring the material out (fig. 9-17).

The slope of the ramp depends on the type of loader

operated; for example, a crawler-mounted loader may

dig a more abrupt approach to the excavation.

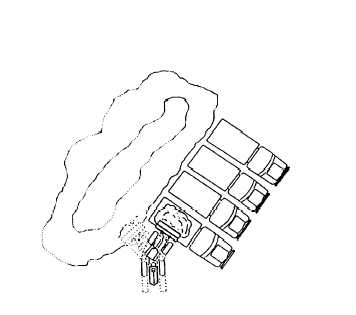

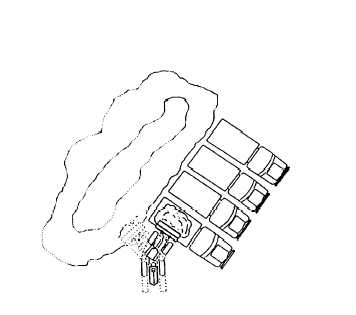

When loading from a bank or stockpile, use the “V”

method shown in figure 9-18 or the step-loading method

shown in figure 9-19. Position the dump truck at about

a 30-degree to a 45-degree angle from the stockpile.

Additionally, when possible, load the dump truck

downwind to prevent dirt and dust from blowing back

into your face. Keep the truck close to the work area to

minimize loader travel, and keep the work area clean

and level.

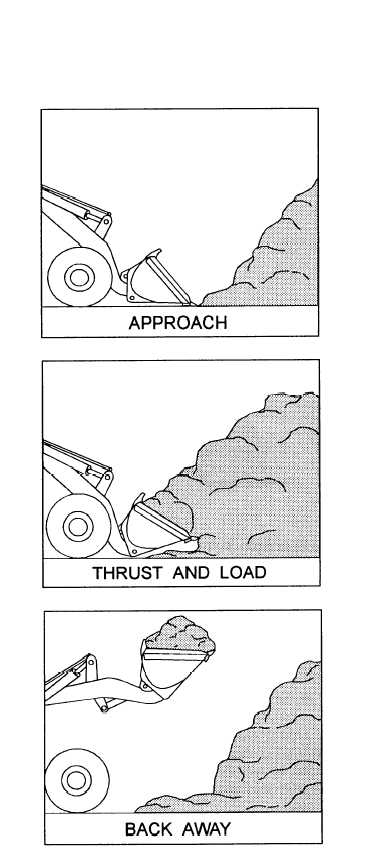

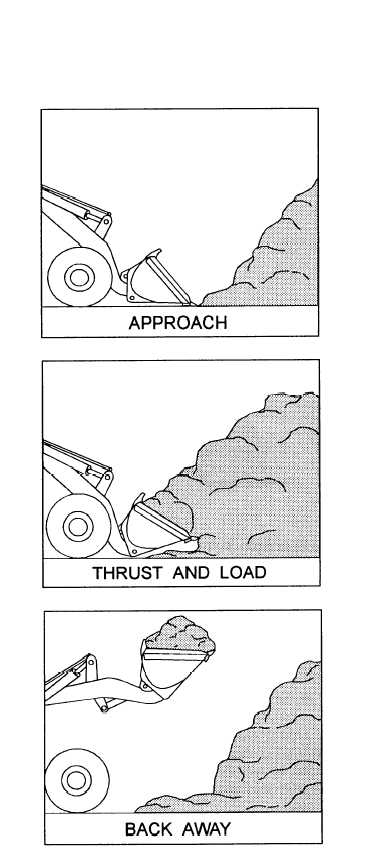

The bucket is loaded by moving the loader forward

with the bucket at the desired digging level and with the

engine at full-governed speed. As the bucket penetrates

the material, raise the bucket slightly. When the material

fills to the top of the spill board, roll the bucket all the

way back (fig. 9-20). The rollback position is main-

tained to prevent spillage while backing away.

When transporting material, raise the lift arm to give

the bucket the same ground clearance as provided by the

loader axle. Keep the travel speed reasonable for safe

operation. Upon reaching the truck, raise the bucket high

enough to clear the truck body. Reduce forward speed

and dump the load in the center of the dump bed, as

Figure 9-20.—Bucket-loading technique.

9-9