has been loaded, scrape up a little dirt that will push the

object back further into the bowl.

To unload the object, shift the ejector from forward

to reverse several times to move the object around so it

will fall out. After the object has been unloaded, turn

the tractor sharply so the scraper clears the unloaded

object.

NOTE: Use extreme care when handling large

objects. Oversize objects, such as large rocks, can cause

damage by denting, bending, or straining parts. Damage

may also be done by accidental collision with large rocks

during ordinary digging.

PRODUCTION TECHNIQUES

Scraper production techniques are used to achieve

the most amount of work with the scrapers assigned.

These techniques are as follows.

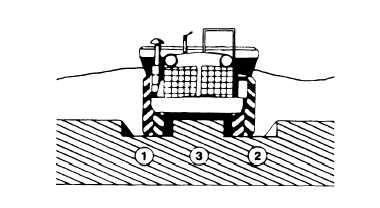

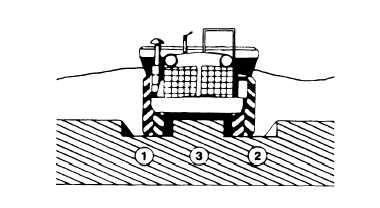

Figure 10-44.-Straddle loading.

Downhill Loading

Downhill loading uses the force of gravity on the

scraper to get larger loads in less time. The added force

of gravity is 20 pounds per gross ton of weight per 1

percent of downhill grade. The downhill pull adds more

material per load, and the added material weight

increases the total gravitational pull.

Straddle Loading

Straddle loading gains time on every third trip

because the center strip loads with less resistance than

a full cut. After the first scraper has made a cut, the

second scraper should make a parallel cut and leave a 4-

to 5-foot-wide island between the two cuts, as shown in

figure 10-44. The third scraper can straddle this island

of material to achieve a fast, less resistance load.

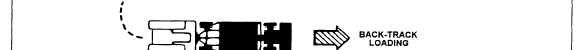

Back-track Loading

Back-track loading is the method where the cut is

fairly short and loading in both directions is impractical.

As shown in figure 10-45, too much time is spent back

tracking and maneuvering the push cat for the next load.

When the cut is wide enough, other methods should be

tried.

Shuttle Loading

Shuttle loading is used for short cuts where it is

possible to load in both directions, as shown in figure

10-46. The push cat pushes one scraper in one direction,

then turns and push loads a second scraper in the

opposite direction.

Figure 10-45.-Back-track loading.

10-24