fill. When traveling too close to the next scraper, spread

the load at the far end of the fall.

NOTE: Keep the scraper bowl as close to the

ground as possible to lower its center of gravity and to

keep it upright.

Spreading

Techniques for scraper spreading operations are as

follows:

l Spread the first load at the start of the fill.

l Travel with subsequent loads over the previous

fill, provided lifts are small.

. Make each following spread start at the end of

the previous layer.

. Finish spreading in one full length before starting

a new lane, so rollers can begin compaction.

. Route the scrapers to compact the fill. Over-

lapping the scraper tire tracks aids in the compaction of

the entire area and reduces the compaction time

necessary with a roller.

l Spread in the highest gear permitted by the

condition of the fill area terrain.

NOTE: Slowly discharging loads at low speed

slows down production and cycle time.

l Do not waste time on the fill. As soon as the load

is spread, get the scraper back on the haul road and return

to the cut. Plan your exit from the fill to avoid soft

ground and detours around trees and other obstacles.

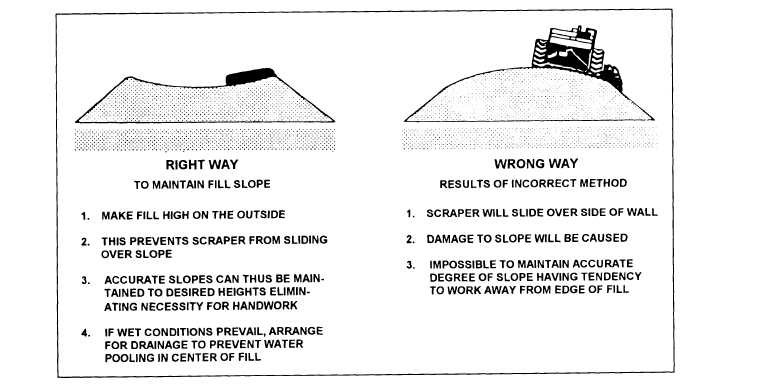

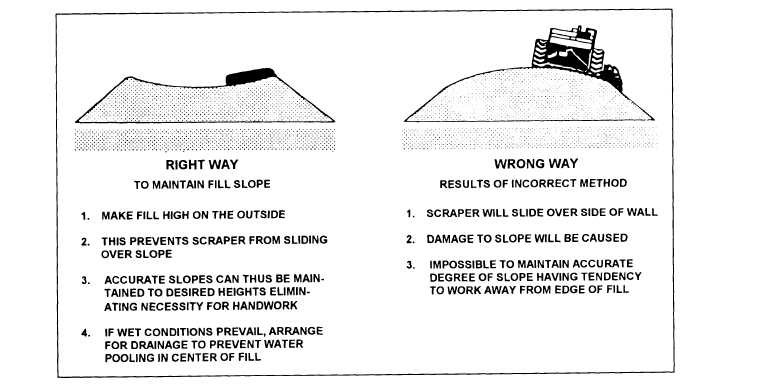

. As shown in figure 10-49, make the fill high on

the outside edge. This prevents the scraper from sliding

over the outside edge and helps in maintaining accurate

slopes to desired heights. When the fill is not made in

this manner, the scraper tends to work away from the

edge of the fill, making it hard to maintain the correct

slope. In inclement weather, build the low center up for

drainage.

SCRAPER SAFETY

Safety precautions that apply to scrapers are as

follows:

. Never operate a scraper at speeds that are unsafe.

. Always wear seat belts. Uneven terrain can

cause a violent tilt of the scraper, causing possible

personal injury by throwing you off or against the

steering wheel if NOT secured in the operator’s seat.

Figure 10-49.-Proper placement of fill material.

10-27