Figure 11-44.-Steel-wheeled roller.

Figure 11-45.—Drive wheel rolling action.

Pneumatic-tired rollers may be equipped with 15-,

17-, 20-, or 24-inch tires. Air pressure in the tires may

vary for different types of material, such as 50 to 60 psi

to finish asphalt and 100 psi to compact a granular

subbase. The tires must be inflated to nearly equal

pressure with variation not exceeding 5 psi to apply

uniform pressure during rolling.

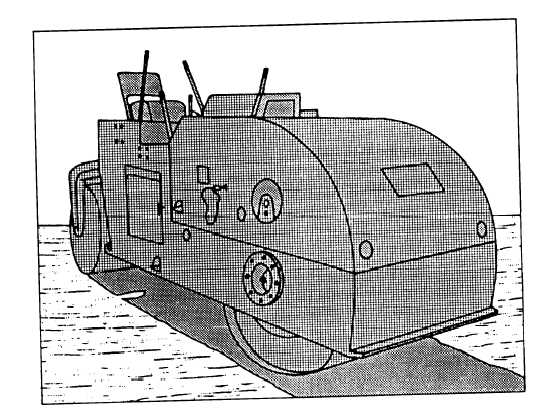

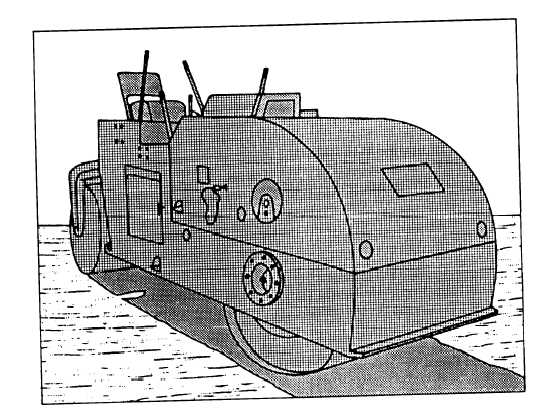

coarse materials and asphalt. This roller produces a

smooth, solid surface under favorable conditions, but

may fail to compact areas narrower than the roll, and do

not compact deeply in proportion to their weight. The

steel- wheeled roller does not change shape to bring

suitable support for itself. Rather it sinks until enough

bearing area has come in contact with the roll to support

Figure 11-43 shows the action of a pneumatic-tired

the roller weight.

roller. Pneumatic-tired rollers are used because the

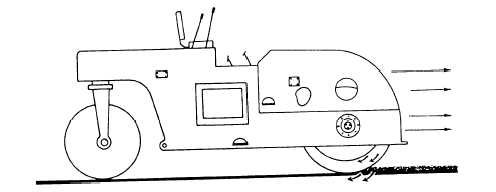

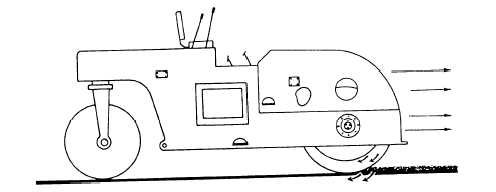

The drive wheel is ahead of the tiller wheel in the

individual wheels can exert a kneading action in small

direction of travel. The tiller wheel functions as the

areas that wide, rigid steel drums tend to bridge.

steering axle. As shown in figure 11-45, there is a

STEEL-WHEELED ROLLERS

A steel-wheeled roller, as shown in figure 11-44, is

used for compaction and finish operations on base

downward vertical force caused by the weight or the

wheel. The arrows, concentric with the steel wheel,

represent the rotational force on the wheel. This force is

transmitted to the base of the wheel, as the roller is

11-23