can be kept clean inside and variations from

normal operation can easily be detected and

remedied.

OPERATION OF HYDRAULIC

COMPONENTS

To transmit and control power through

pressurized fluids, an arrangement of inter-

connected components is required. Such an

arrangement is commonly referred to as a system.

The number and arrangement of the components

vary from system to system, depending on the

particular application. In many applications, one

main system supplies power to several subsystems,

which are sometimes referred to as circuits. The

complete system may be a small compact unit;

more often, however, the components are located

at widely separated points for convenient control

and operation of the system.

The basic components of a fluid power system

are essentially the same, regardless of whether the

system uses a hydraulic or a pneumatic medium.

There are five basic components used in a system.

These basic components are as follows:

1.

2.

3.

4.

5.

Reservoir or receiver

Pump or compressor

Lines (pipe, tubing, or flexible hose)

Directional control valve

Actuating device

Several applications of fluid power require

only a simple system; that is, a system which uses

only a few components in addition to the five

basic components. A few of these applications are

presented in the following paragraphs. We will

explain the operation of these systems briefly at

this time so you will know the purpose of each

component and can better understand how

hydraulics is used in the operation of these

systems. More complex fluid power systems are

described in chapter 12.

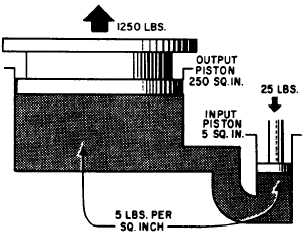

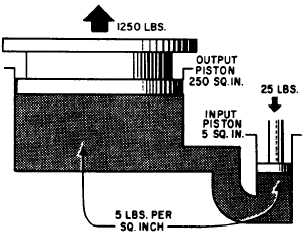

HYDRAULIC JACK

The hydraulic jack is perhaps one of the

simplest forms of a fluid power system. By

moving the handle of a small device, an individual

can lift a load weighing several tons. A small

initial force exerted on the handle is transmitted

by a fluid to a much larger area. To understand

this better, study figure 2-19. The small input

piston has an area of 5 square inches and is

directly connected to a large cylinder with an

output piston having an area of 250 square inches.

The top of this piston forms a lift platform.

If a force of 25 pounds is applied to the input

piston, it produces a pressure of 5 psi in the fluid,

that is, of course, if a sufficient amount of

resistant force is acting against the top of the

output piston. Disregarding friction loss, this

pressure acting on the 250 square inch area of the

output piston will support a resistance force of

1,250 pounds. In other words, this pressure could

overcome a force of slightly under 1,250 pounds.

An input force of 25 pounds has been transformed

into a working force of more than half a ton;

however, for this to be true, the distance traveled

by the input piston must be 50 times greater than

the distance traveled by the output piston. Thus,

for every inch that the input piston moves, the

output piston will move only one-fiftieth of an

i n c h .

This would be ideal if the output piston needed

to move only a short distance. However, in most

instances, the output piston would have to be

capable of moving a greater distance to serve a

practical application. The device shown in figure

2-19 is not capable of moving the output piston

farther than that shown; therefore, some other

means must be used to raise the output piston to

a greater height.

Figure 2-19.—Hydraulic jack.

2-15