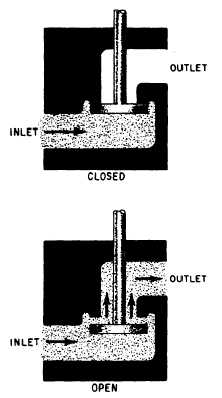

when the valve is open. A small piston (9) is

attached to the bottom of the spool valve.

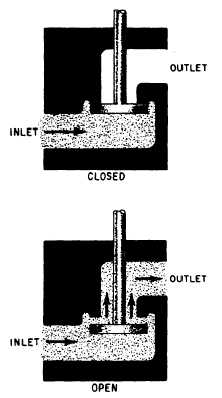

When the valve is in the closed position, the

top piston of the spool valve blocks the discharge

port (8). With the valve in this position, fluid

flowing from the actuating unit enters the inlet

port (5). The fluid cannot flow through the valve

because discharge port 8 is blocked. However,

fluid will flow through the pilot passage (6) to the

small pilot piston. As the pressure increases, it acts

on the pilot piston until it overcomes the preset

pressure of spring 3. This forces the valve spool

(4) up and allows the fluid to flow around the

shaft of the valve spool and out discharge port

8. Figure 6-20 shows the valve in this position.

During reverse flow, the fluid enters port 8. The

spring (3) forces valve spool 4 to the closed

position. The fluid pressure overcomes the spring

tension of the check valve (7). The check valve

opens and allows free flow around the shaft of

the valve spool and out through port 5.

The operating pressure of the valve can be

adjusted by turning the adjustment screw (1),

which increases or decreases the tension of the

spring. This adjustment depends on the weight

that the valve must support.

It is normal for a small amount of fluid to leak

around the top piston of the spool valve and into

the area around the spring. An accumulation

would cause additional pressure on top of the

spool valve. This would require additional

pressure to open the valve. The drain (2) provides

a passage for this fluid to flow to port 8.

DIRECTIONAL CONTROL VALVES

Directional control valves are designed to

direct the flow of fluid, at the desired time, to the

point in a fluid power system where it will do

work. The driving of a ram back and forth in its

cylinder is an example of when a directional

control valve is used. Various other terms are used

to identify directional valves, such as selector

valve, transfer valve, and control valve. This

manual will use the term directional control valve

to identify these valves.

Directional control valves for hydraulic

and pneumatic systems are similar in design

and operation. However, there is one major

difference. The return port of a hydraulic valve

is ported through a return line to the reservoir,

while the similar port of a pneumatic valve,

commonly referred to as the exhaust port, is

usually vented to the atmosphere. Any other

differences are pointed out in the discussion of

the valves.

Directional control valves may be operated by

differences in pressure acting on opposite sides

of the valving element, or they maybe positioned

manually, mechanically, or electrically. Often two

or more methods of operating the same valve will

be used in different phases of its action.

CLASSIFICATION

Directional control valves may be classified in

several ways. Some of the different ways are by

the type of control, the number of ports in the

valve housing, and the specific function of the

valve. The most common method is by the type

of valving element used in the construction of the

valve. The most common types of valving

elements are the ball, cone or sleeve, poppet,

rotary spool, and sliding spool. The basic

operating principles of the poppet, rotary spool,

and sliding spool valving elements are discussed

in this text.

Poppet

The poppet fits into the center bore of the seat

(fig. 6-21). The seating surfaces of the poppet and

the seat are lapped or closely machined so that

the center bore will be sealed when the poppet is

Figure 6-21.—Operation of a simple poppet valve.

6-15