is no provision for retracting the ram by fluid

power, when fluid pressure is released, either the

weight of the object or some mechanical means,

such as a spring, forces the ram back into the

cylinder. This forces the fluid back to the

reservoir.

The single-acting ram-type actuating cylinder

is often used in the hydraulic jack. The elevators

used to move aircraft to and from the flight deck

and hangar deck on aircraft carriers also use

cylinders of this type. In these elevators, the

cylinders are installed horizontally and operate the

elevator through a series of cables and sheaves.

Fluid pressure forces the ram outward and lifts

the elevator. When fluid pressure is released from

the ram, the weight of the elevator forces the ram

back into the cylinder. This, in turn, forces the

fluid back into the reservoir.

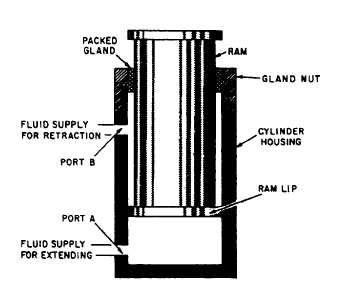

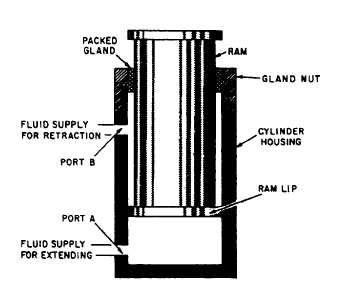

Double-Acting Ram

A double-acting ram-type cylinder is illustrated

in figure 10-2. In this cylinder, both strokes of

the ram are produced by pressurized fluid. There

are two fluid ports, one at or near each end of

the cylinder. Fluid under pressure is directed to

the closed end of the cylinder to extend the ram

and apply force. To retract the ram and reduce

the force, fluid is directed to the opposite end of

the cylinder.

A four-way directional control valve is

normally used to control the double-acting ram.

When the valve is positioned to extend the ram,

pressurized fluid enters port A (fig. 10-2), acts on

Figure 10-2.—Double-acting ram-type actuating cylinder.

the bottom surface of the ram, and forces the ram

outward. Fluid above the ram lip is free to flow

out of port B, through the control valve, and to

the return line in hydraulic systems or to the

atmosphere in pneumatic systems.

Normally, the pressure of the fluid is the same

for either stroke of the ram. Recall from chapter

2 that force is equal to pressure times area

(F= PA). Notice the difference of the areas upon

which the pressure acts in figure 10-2. The

pressure acts against the large surface area on the

bottom of the ram during the extension stroke,

during which time the ram applies force. Since

the ram does not require a large force during the

retraction stroke, pressure acting on the small area

on the top surface of the ram lip provides the

necessary force to retract the ram.

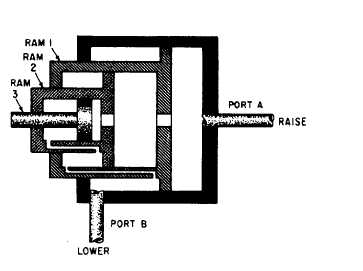

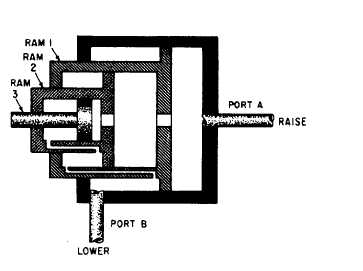

Telescoping Rams

Figure 10-3 shows a telescoping ram-type

actuating cylinder. A series of rams is nested in

the telescoping assembly. With the exception of

the smallest ram, each ram is hollow and serves

as the cylinder housing for the next smaller ram.

The ram assembly is contained in the main

cylinder assembly, which also provides the fluid

ports. Although the assembly requires a small

space with all the rams retracted, the telescoping

action of the assembly provides a relatively long

stroke when the rams are extended.

An excellent example of the application of this

type of cylinder is in the dump truck. It is used

to lift the forward end of the truck bed and dump

the load. During the lifting operation, the greatest

force is required for the initial lifting of the load.

Figure 10-3.—Telescoping ram-type actuating cylinder.

10-2