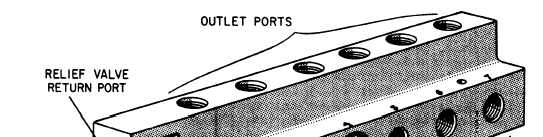

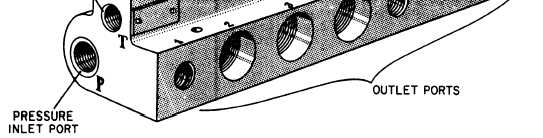

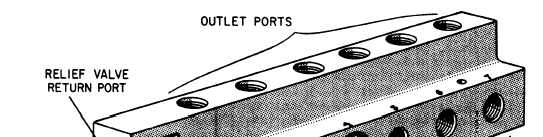

A simple manifold is illustrated in figure 5-24.

This manifold contains one pressure inlet port and

several pressure outlet ports that can be blocked

off with threaded plugs. This type of manifold

can be adapted to systems containing various

numbers of subsystems. A thermal relief valve

may be incorporated in this manifold. In this case,

the port labeled T is connected to the return line

to provide a passage for the relieved fluid to flow

to the reservoir.

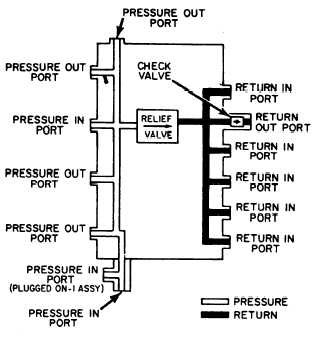

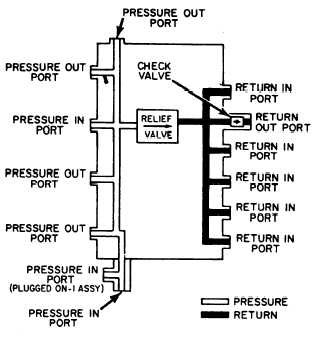

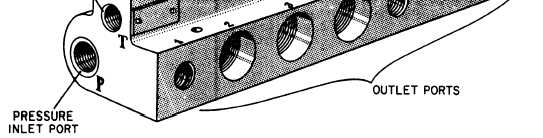

Figure 5-25 shows a flow diagram in a

manifold which provides both pressure and return

passages. One common line provides pressurized

fluid to the manifold, which distributes the fluid

to any one of five outlet ports. The return side

of the manifold is similar in design. This manifold

is provided with a relief valve, which is connected

to the pressure and return passages. In the event

of excessive pressure, the relief valve opens and

allows the fluid to flow from the pressure side of

the manifold to the return side.

Figure 5-25.—Fluid manifold—flow diagram.

PRECAUTIONARY MEASURES

The fabrication, installation, and maintenance

of all fluid lines and connectors are beyond the

scope of this training manual. However, there are

some general precautionary measures that apply

to the maintenance of all fluid lines.

Regardless of the type of lines or connectors

used to make up a fluid power system, make

certain they are the correct size and strength and

perfectly clean on the inside. All lines must be

absolutely clean and free from scale and other

foreign matter. Iron or steel pipes, tubing, and

fittings can be cleaned with a boiler tube

wire brush or with commercial pipe cleaning

apparatus. Rust and scale can be removed from

short, straight pieces by sandblasting, provided

there is no danger that sand particles will remain

lodged in blind holes or pockets after the piece

Figure 5-24.—Fluid manifold.

5-20