Figure 2-1.—Geometric orientation of the LM2500 GTE

The following section discusses the borescope

procedures used to inspect the LM2500 GTE. The

inspection procedures and the knowledge gained from

damage evaluation may also be applied to the borescope

inspection of the Allison 501-K17 GTE.

GENERAL INSPECTION PROCEDURES

It is a good engineering practice to review the

machinery history of an engine before you conduct an

inspection Various component improvement programs

will eventuallyy effect all engines in service. A rebuilt or

modified engine may contain improved parts that differ

from the original. An example of this is the first-stage

compressor midspan damper that may have its original

coating, an improved coating, or a carboloy shoe welded

on at the midspan damper interface. If you review the

machinery history, you will discover the status of those

parts that have been changed or modified.

Assuming that the engine history is normal and

FOD is not suspected, you should be aware of the

following factors when conducting a borescope

inspection:

Know your equipment.

Locate all inspection areas and ports.

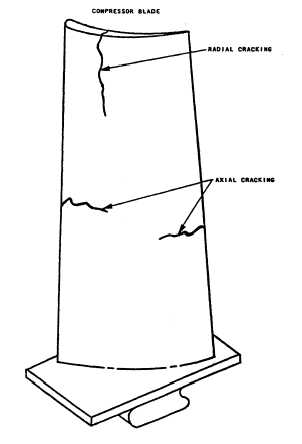

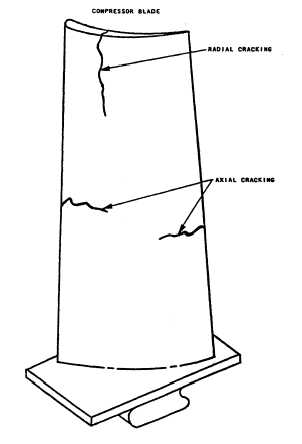

Figure 2-2.—Example of radial and axial cracking.

2 - 2