EXPANSION BENDS

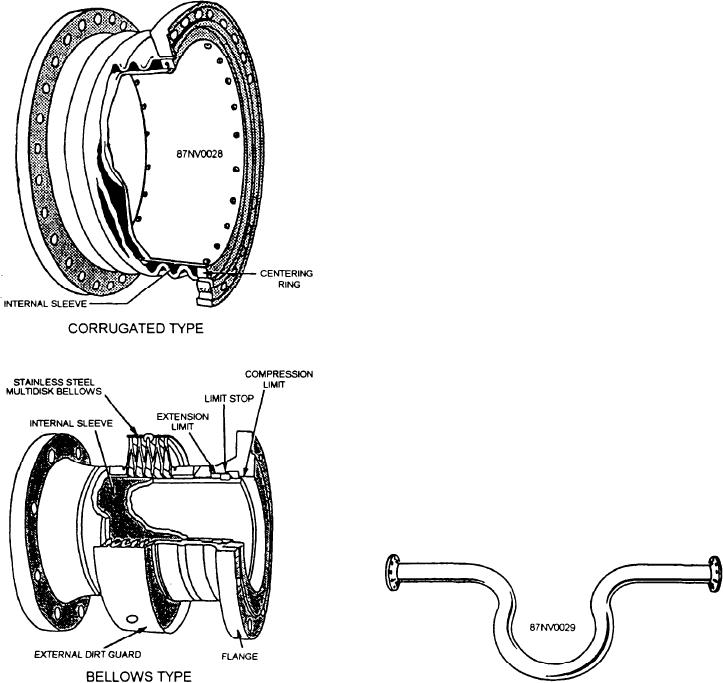

Corrugated and bellows-type expansion joints (fig.

15-29) are used for both medium- and high-pressure

Loops, U-shaped bends, and offsets are fitted into

piping systems aboard ship. These joints are used to

piping systems so that the expansion or contraction will

allow both axial and radial movement of main steam

be absorbed by the bending in the pipe that forms the

piping where it passes through the bulkhead.

bend. Because expansion bends are more reliable and

Corrugated and bellows-type expansion joints are

normally less expensive than expansion joints, they are

made of various materials, including hard rubber,

preferred when conditions permit their use. Figure

copper, nickel, and stainless steel. The accordion-like

15-30 shows a common type of expansion loop.

action of the corrugation or of the bellows allows the

Expansion bends and joints can be flexed in both

system to expand or contract. The movement of the

directions from their normal position. They should be

pipe is absorbed by the changing curvature of the

installed so that they are stressed in one direction when

corrugations or of the bellows.

the piping is cold, and stressed in the other direction

when the piping is hot. The amount and direction of the

prestress or cold pull-up to be applied to piping and

expansion bends or joints is indicated on the appropriate

ship's plans. These instructions must be followed

carefully to prevent failure of the expansion joints,

piping, and connected equipment.

COLD SPRING JOINTS

Another method used to provide for expansion in

high-pressure piping is the cold spring joint. The pipe

for this joint is cut short an amount usually equal to one

half the computed expansion. After the system is

fabricated and ready for installation, a dutchman (an

accurately machined blank flange), equal in thickness

to the required amount of cold spring, is inserted

between the flanges of the cold spring joint. When all

other connections have been made, the dutchman is

removed and the joint set up to about 40,000 psi with

temporary pull-up bolts. The temporary bolts are then

replaced one by one with permanent installation bolts

set up to the required bolt stress.

WELDED AND BRAZED JOINTS

The majority of joints found in subassemblies of

piping systems are welded joints, especially in

high-pressure piping. The welding is done according to

standard specifications that define the materials and

Figure 15-29.--Corrugated and bellows-type expansion joints.

Figure 15-30.--Expansion loop.

15-32