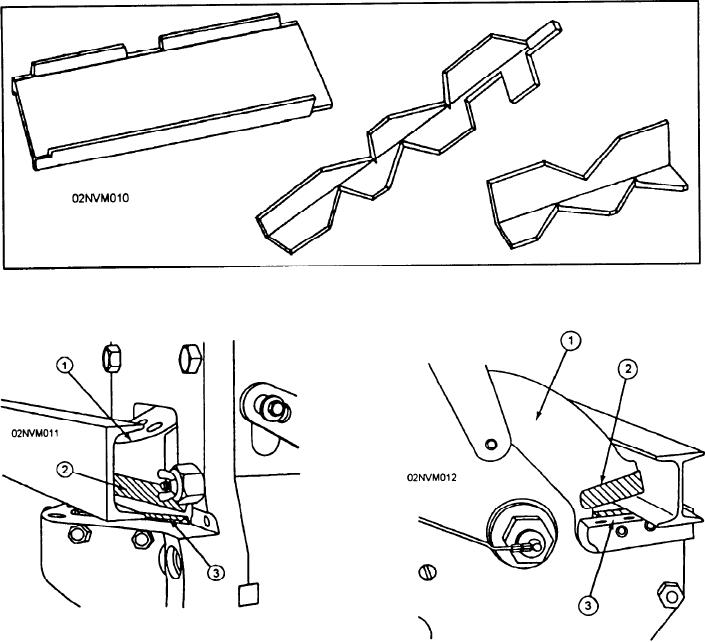

Figure 13-30.--Typical notcher and coper work.

1. Punch Holder

2. Notcher Puncher

1. Punch Holder

3. Die Holder

2. Coper Punch

Figure 13-31.--Universal ironworker notcher punch.

3. Die Holder

Figure 13-32.--Universal ironworker coper punch.

knives are firmly fastened since they have a tendency

to work loose during use.

Pullmax

2. Cycle the machine through one complete

revolution, checking the machine for binding or

The Pullmax machine is one of the most important

misalignment.

timesaving machines in the shipfitter shop. It is also

one of the most underutilized machines in the shipfitter

3. Place the workpiece between the cutting knives

shop. It is capable of shearing, nibbling, slot-cutting,

and adjust the holddowns, if installed, to support the

beading, edge-bending, dishing, and numerous other

material being cut and to prevent kickback.

operations depending on setup and tooling. The

4. Ensure that the material to be cut is supported

Pullmax is being included in this section on cutting

on two sides of the die to prevent kickup and rolling

metals since that is its primary function in the shipfitter

during the cutting evolution.

shop. For the purpose of this training manual, we will

only discuss the shearing capabilities of the machine. If

5. Step on the foot pedal and hold the pressure

you want to become more familiar with the capabilities

until the knives have cut the workpiece.

13-27