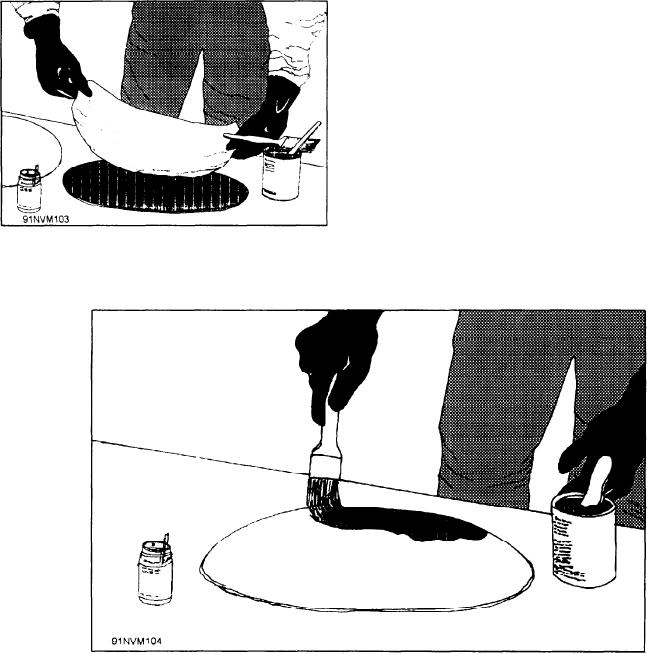

Center a bonding ply over the preformed patch as shown

patching by abrading the scarfs around the holes.

in figure 4-23, and saturate it with resin. (See fig. 4-24.)

Patch one skin and allow it to cure. After this patch

Repeat this procedure with the other bonding plies.

has cured, cut and fit the core section. Secure the core

Position this assembly over the hole as shown earlier in

section with repair resin. Then, repair the second skin.

figure 4-14, and cover it with a sheet of separating film.

Where damage is to only one skin and core, cut

The patch can be held in place by a cover plate, or by

out a circle of skin with a sharp-cutting tool such as a

shoring as shown earlier in figure 4-13 until the patch

hole saw. Cut the skin away from the core material

hardens or cures. The patch is completed in the same

with a knife. Damaged honeycomb core can be cut

manner as previously described.

with sharp shears and pulled out with needle nose

pliers. Other types of core material, such as plastic

Repairing Double-Skin Plastic Boats

foam, can be cut out with a knife. Cut a piece of core

material to fit the section that was cut out. Be careful

To repair damage that extends through both skins

to match the pattern, if necessary. Cement the material

and the core section of plastic boats, follow the

in place with repair resin and proceed to repair the

procedures described earlier under repair procedures.

outer skin as described previously.

Cut out the damaged areas and prepare the skins for

Damage to the skin only can be repaired in the

same way as a conventional repair to reinforced

plastic.

METAL BOATS

From a wide range of aluminum alloys available

for many purposes, the Navy selected those most

suitable for salt water use for boat hulls. The hulls of

Navy aluminum boats are usually constructed of either

alloy 5086 or 5456. Both alloys contain magnesium as

the primary alloying ingredient, but differ slightly in

strength. In general, these two alloys are not used in

combination except when emergency repairs are

Figure 4-23.--Centering the first bonding ply.

needed.

Figure 4-24.--Saturation of the bonding ply with resin.

4-20